CNC Plasma Cutter Will Be to Australia

CNC Plasma Cutter Australia

CNC plasma cutter will be to australia Our customers often introduce our company to their friend. Because they believe the quality of our machines and our company. Many thanks to our customers.

Our Australia customers bought our 1325 ATC CNC router in 2021. After using the machine for a long time, he felt that the quality of our machine was very good. When his friend asked him this machine, he recommended our company to his friend. This friend told our sales his processing needs. So our sales recommend the cnc plasma cutter to him.

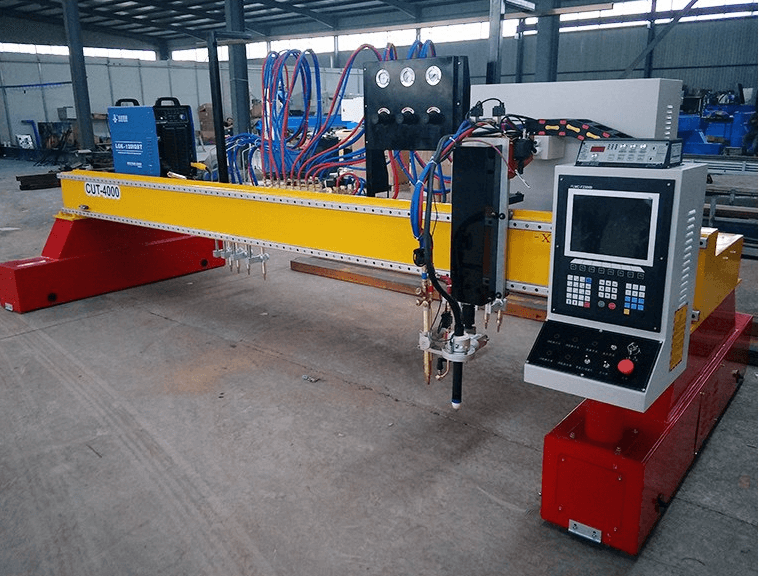

CNC plasma cutting refers to the cutting of metals using a plasma torch controlled from a computer. Plasma cutters operate by forcing a gas or compressed air at high speeds through a nozzle. Once an electric arc is introduced to the gas, ionized gas or plasma is created, the fourth state of matter. It, in turn, cuts through the metal. CNC Plasma cutter or CNC Plasma cutting machine is mainly used for carbon steel, metal, steel and steel tube cutting with 0-50mm thickness and stainless steel 0-20mm cutting. It is a cost-effective machine for metal cutting and the price is lower than the Fiber laser or YAG laser machines but it can cut very thick of steel and with very good cutting performance.

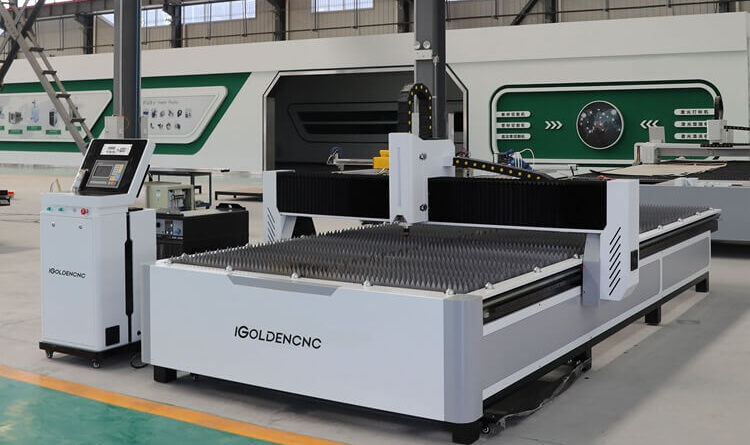

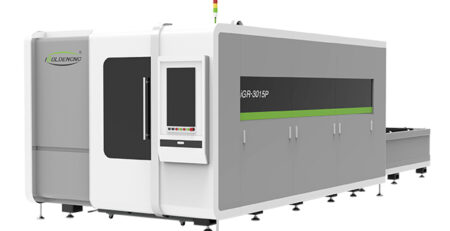

IGOLDENCNC Plasma Cutter

4×8 CNC plasma cutting table is an automatic power tool with CNC plasma cutting system, which is equipped with 48″ x 96″ table size. The best budget CNC plasma table is mainly used for full sheet metal cutting in home shop, small shop, school education, or industrial manufacturing.

Plasma cutting cnc advantage & features

- The Plasma Cutting Machine can cut all metal sheets. The cutting area is very wide.

- The plasma power supply we use is the best pilot arc plasma cutter. Equipped with a good plasma cutting torch, it is suitable for cutting most metals, such as stainless steel, alloy, aluminum, low carbon steel, carbon steel, etc. Whether you are a professional user or a DIY user, it will provide you with professional cutting functions. Powerful and reliable product, you should not miss it!

- The cutting speed of the metal cutting machine is very fast and the efficiency is high. The cutting speed can reach more than 10m/min.

- The cutting precision is higher than the flame cutting machine. The underwater cutting has no deformation, and the fine plasma cutting has higher precision.

- The Plasma Cutting Machines use a professional plasma CNC system. It is all offline work and humanized operation.

- The CNC Plasma uses the advanced USB interface to work offline with fast data transmission and does not occupy computer resources.

- This Metal Cutting Machine can be compatible with a variety of software.

- The machine is with the function of continued carving when power outage and breakpoint. And the function of processing time prediction and automatic tool setting.

- Affordable factory direct price and one year warranty.

Types of Plasma Cutters

Plasma cutters are available in various sizes and configurations to accommodate different cutting requirements. They can be categorized into handheld or portable units and larger, mechanized or CNC-controlled systems. Handheld units are more portable and suitable for small-scale or on-site cutting tasks, while mechanized or CNC-controlled plasma cutters are used for larger-scale production and automated cutting operations.

Cutting Accuracy and Quality: Plasma cutter provide excellent cutting accuracy and quality, especially when used with CNC control. CNC-controlled plasma cutters can follow intricate cutting paths and produce complex shapes with high precision. The cut quality can be influenced by factors such as the machine’s power, cutting speed, gas selection, and torch design.

Leave a Reply

You must be logged in to post a comment.