CNC Bridge Saw

In the dynamic world of stone fabrication, the pursuit of uncompromising precision, efficiency, and versatility has become a driving force. At the forefront of this evolution stands a transformative piece of equipment known as the CNC bridge saw. These cutting-edge solutions are redefining the standards of modern stone processing, empowering fabricators, stonemasons, and contractors to unlock new levels of productivity, quality, and competitiveness.

CNC Bridge Saw

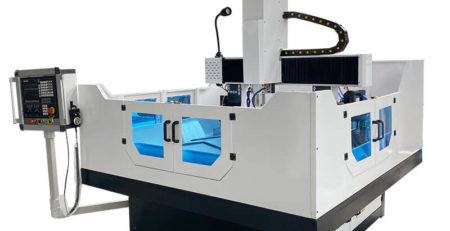

CNC (Computer Numerical Control) bridge saws are specifically designed to handle the unique requirements of processing a wide range of natural and engineered stone materials, including granite, marble, quartz, and more. These advanced systems utilize computer-controlled cutting blades to perform intricate cutting, shaping, and profiling tasks with exceptional precision and automation.

Bridge saw is a machine used to achieve fast cutting of large stones and industrial masonry, and is widely used in the stone processing industry. It usually consists of a large platform and a moving cutting head, which can accurately perform straight and bevel cutting. Bridge saw can handle various types of stone, such as marble, granite and artificial stone, and is often used to make countertops, floor tiles and sculptures. Its working principle is to cut the stone into the required shape and size through the high-speed rotating cutting blade.

Common bridge saw on the market include 4-axis bridge saw, 5-axis bridge saw, and 4+1-axis bridge saw machine. These three types of bridge saws are the most common.

4 Axis Bridge Saw

The 4-axis bridge cutting machine is a high-precision stone cutting equipment equipped with four independent axes of motion, usually including X, Y, Z axes and a rotation axis. This design allows the machine to perform complex cuts and carvings in multiple directions, capable of handling complex shapes and details, and is suitable for creating countertops, sculptures, and other custom stone products. The 4-axis bridge cutting machine has significant advantages in improving cutting efficiency and precision, and is suitable for high-demand stone processing tasks.

5-Axis Bridge Saw

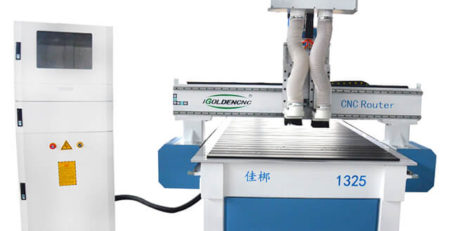

The 5-axis bridge saw is an advanced stone processing equipment with five motion axes, including X, Y, Z, and two rotation axes. This enables the machine to cut and engrave at multiple angles and directions, and can complete more complex shapes and details.

4+1 Bridge Saw

The 4+1 axis bridge cutting machine is a high-precision device used for cutting materials such as stone, ceramics, and metal. It has four main axes and an additional axis (usually a rotating axis). The 4 main axes allow complex cutting in the horizontal and vertical directions, while the additional axis provides additional rotation capabilities, capable of processing more complex shapes and angles.

Bridge Saw Machine Price

| Type of Bridge Saw | Price of Bridge Saw |

| 4 Axis Bridge Saw | 10000$-40000$ |

| 5 Axis Bridge Saw | 40000$-80000$ |

| 4+1 CNC Bridge Saw | 14000$-50000$ |

Bridge cutting machines are professional mechanical equipment, and their prices are affected by many factors, including brand, model, function, configuration, etc. Among them, the configuration and function of the bridge cutting machine are the main factors that determine the price of the bridge cutting machine. The price varies according to different configurations.

4-axis bridge cutting machines are widely used in stone processing, ceramic processing and other fields. According to market information, the price range of 4-axis bridge cutting machines is roughly between US$30,000 and US$40,000, and the price fluctuates according to the change of configuration. For example, some brands of entry-level 4-axis bridge cutting machines may cost around US$10,000, while high-end models or models with more special functions may cost more.

Compared with 4-axis bridge cutting machines, 5-axis bridge cutting machines have higher processing accuracy and flexibility, and can meet more complex processing needs. Therefore, their prices are usually higher. The price range of 5-axis bridge cutting machines on the market is relatively wide, ranging from US$40,000 to US$80,000. The specific price depends on the performance, configuration, brand and market supply and demand of the equipment.

The 4+1-axis bridge cutting machine adds an additional axis to the 4-axis bridge cutting machine, which is usually used to achieve more complex processing tasks or improve processing efficiency. Generally speaking, the price of a 4+1-axis bridge cutting machine will be higher than that of an ordinary 4-axis bridge cutting machine, and the price is about US$10,000 to US$50,000. However, the specific price needs to be determined according to the specific situation of the equipment.

CNC Bridge Saw Application

The 5 axis CNC stone bridge saw is good at cutting, milling, chamfering and edging quartz, marble, artificial stone and slabs in regular and irregular shapes. It can realize countertop cutting, bridge cutting, roman column cutting, arc line cutting, concave-convex cutting, and irregular edge cutting and milling. The automatic stone cutting bridge saw can process products of sanitary ware, stone furniture, interior decoration, and other fields. For example, wash basins, bathroom countertop, stone tables, dinning tables, kitchen tables, kitchen cabinet basins, background wall, roman edge stone decorations, etc.

Key Considerations for Selecting the Optimal CNC Bridge Saw

As you explore the integration of CNC bridge saw technology into your stone fabrication operations, there are several critical factors to consider:

- Material Compatibility: Ensure that the CNC bridge saw is designed to handle the specific stone materials you work with, considering factors such as hardness, abrasiveness, and composition.

- Cutting Precision and Quality: Prioritize machines that offer the highest levels of cutting precision and the ability to produce consistent, high-quality edges on your fabricated stone components.

- Automation and Workflow Integration: Look for CNC bridge saws that seamlessly integrate with your existing production workflows, including material handling systems and digital design software.

- Safety and Ergonomic Features: Evaluate the machine’s safety mechanisms and ergonomic design to protect your workforce and enhance overall workplace satisfaction.

- Scalability and Future-Proofing: Consider the growth trajectory of your business and select a CNC bridge saw that can scale to accommodate your evolving stone fabrication needs.

Can I Make Money with A CNC Bridge Saw Machine?

The answer is yes. Bridge cutting machines are widely used in the field of material processing, mainly for cutting, engraving, grooving and other processes. They are widely used in the construction industry, decoration industry, tombstone industry, and stone processing industry.

Construction industry: Bridge cutting machine equipment is widely used in the construction industry to cut marble and granite decoration projects such as floors, walls, and ceilings. These materials can present perfect decorative effects and enhance the overall beauty of the building after precise cutting by the bridge cutting machine.

Decoration industry: Bridge cutting machine equipment also plays an important role in the decoration industry. It can not only cut out complex stone carving techniques such as plum blossom locks, but also perform fine engraving and grooving according to design requirements to meet the needs of various decorative styles.

In furniture manufacturing, it is often used to cut the stone parts of furniture such as dining tables and coffee tables to achieve personalized customization and aesthetic improvement of furniture.

Tombstone production: Bridge cutting machines can be used to cut various tombstones such as horizontal and vertical tombstones to ensure that the size and shape of the tombstones are accurate, while improving manufacturing efficiency and reducing costs.

Stone processing industry: Bridge saws can accurately cut and process stone and slabs for building decoration, floor paving, etc. Some high-end bridge saws, such as 4+1 axis bridge saws, not only have cutting functions, but also have additional functions such as milling cutters, which can process complex patterns, such as Taichung, under-counter basins and other complex-shaped stone products.

Here are some key features and advantages of a CNC Bridge Saw

- Bridge Design: The CNC Bridge Saw is equipped with a sturdy bridge structure that supports the cutting head and moves along multiple axes, allowing for precise and stable cutting of stone slabs and tiles.

- Automated Cutting: With CNC technology, the Bridge Saw can be programmed to execute complex cutting patterns, curves, and angles with high precision, reducing human error and ensuring consistent results.

- Versatile Cutting Options: The CNC Bridge Saw can be used to cut a variety of stone materials, such as granite, marble, quartz, and more, for a wide range of applications in the construction and architectural industries.

- Efficiency and Productivity: By automating the cutting process and optimizing material usage, the CNC Bridge Saw enhances efficiency, reduces waste, and increases productivity in stone fabrication operations.

Conclusion:

CNC bridge saw have emerged as a transformative force in the world of stone fabrication, redefining the standards of precision, efficiency, and innovation. By understanding the remarkable capabilities of these cutting-edge solutions and leveraging their potential, fabricators, stonemasons, and contractors can unlock a new era of production excellence, solidifying their position as leaders in their respective industries. As the demand for cutting-edge, versatile material processing equipment continues to grow, the strategic adoption of CNC bridge saw technology will be a crucial step towards unlocking your organization’s full potential and thriving in the dynamic landscape of modern stone fabrication.

Leave a Reply

You must be logged in to post a comment.