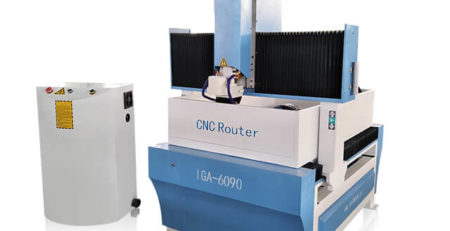

CNC Wood Cutting Carving Machine

CNC wood cutting and carving machines are specifically designed to handle the unique requirements of processing a wide range of wooden materials, from soft woods to hardwoods and engineered composites. These advanced systems utilize computer-controlled cutting tools and carving bits to perform intricate, customized machining tasks with exceptional precision and automation.

CNC Wood Cutting Carving Machine

IGOLDEN ATC CNC router engraving machine, also known as a auto tool changer cnc carving machine, is a powerful and versatile tool that has transformed the way professionals create artwork, carvings, and engravings. This machine features a vertical design that allows it to easily and accurately carve intricate designs onto a variety of materials, including wood, metal, plastic, and even glass.

One of the great advantages of this machine is its ability to automatically exchange tool heads. This means that one can switch from a cutting tool to an engraving tool without stopping the machine. This saves time and effort, enabling the artist to focus on creating more beautiful and intricate designs.

Another advantage of the machine is its precise movement. The vertical design enables the tool head to move up and down with incredible accuracy, which means that it can easily create intricate designs with a high level of detail. The machine also has a variety of speeds and settings, allowing the artist to control the depth of the cut, the speed of the cut, and the direction of the cut. This level of flexibility is critical for creating custom designs that are unique and tailored to the artist’s vision.

Key Features:

- Precision: CNC machines provide high precision in cutting and carving, allowing for intricate designs.

- Automation: They can operate autonomously once programmed, reducing the need for manual labor.

- Versatility: Suitable for various applications, including furniture making, sign-making, and intricate art pieces.

- Speed: Faster than traditional woodworking methods, increasing productivity.

Benefits:

- Consistency: Each piece produced is identical, ensuring uniformity in production.

- Complex Designs: Can create complex shapes and patterns that would be difficult to achieve by hand.

- Reduced Waste: More efficient cutting patterns can minimize material waste.

Key Considerations for Selecting the Optimal CNC Wood Cutting and Carving Machine

As you explore the integration of CNC wood cutting and carving technology into your woodworking operations, there are several critical factors to consider:

- Material Compatibility: Ensure that the CNC wood cutting and carving machine is designed to handle the specific wooden materials you work with, considering factors such as hardness, grain patterns, and composition.

- Cutting and Carving Precision: Prioritize machines that offer the highest levels of cutting and carving precision, ensuring the final wooden components meet your quality standards and creative vision.

- Automation and Workflow Integration: Look for CNC wood cutting and carving machines that seamlessly integrate with your existing design software and production workflows, streamlining your processes and enhancing overall efficiency.

- Safety and Ergonomic Features: Evaluate the machine’s safety mechanisms and ergonomic design to protect your workforce and create a comfortable, productive work environment.

- Scalability and Future-Proofing: Consider the growth trajectory of your business and select a CNC wood cutting and carving machine that can scale to accommodate your evolving woodworking needs and creative ambitions.

CNC Wood Router Machine Application:

Woodworking: wooden door and furniture, windows, tables and chairs,cabinets and panels, 3D wave plate,MDF,computer desk,musical instruments,etc.

Advertising: billboard, logo,sign,3D characters cutting,acrylic cutting,LED/neon channel, literal-hole cut,lightbox mold,stamp,mould,etc.

Die industry: copper sculpture,aluminum engrave,metal molds,plastic sheeting,PVC ,etc.

Decoration: acrylic, density board, artificial stone, organic glass, soft metals like aluminum and copper, etc.

IGOLDEN CNC Wood Rouer

IGOLDEN atc cnc router engraving carving machine is an advanced CNC device that has a solid structure to ensure high -efficiency and high -precision production. The bed and shelf structure of the machine is welded by IGOLDEN CNC itself. The thickness of the steel pipe reaches 10mm thick, and the welding technology workers have more than 10 years of welding experience, thereby ensuring that the welded joints and horizontal levels are perfectly flawless. Increase the service life of the machine.

The main body of the machine tool uses high -quality cast iron materials, with stable performance, moderate weight, and has super load -bearing capacity. At the same time, it also uses the combination of imported linear rails and precision linear sliders as transmission parts to ensure stable operation and high -precision cutting at high speed.

spindle

The HQD spindle of the CNC Atc Cnc Wood Carving Machine is a powerful and cutting-edge tool that promises high precision and excellent performance. This spindle is designed to achieve optimal cutting, engraving, and drilling results with ease, making it an ideal choice for both hobbyists and professionals alike.

With a maximum speed of 24,000 RPM and a power of up to 9KW, the HQD spindle ensures fast, efficient, and smooth cutting operations. It is also equipped with a Air cooling system that keeps the spindle temperature in check, ensuring optimal performance and longevity.

The HQD spindle is also designed to be user-friendly, with a range of features that make it easy to install, operate and maintain. It is equipped with an automatic tool changing system that allows for fast and seamless tool changes, saving time and increasing productivity.

Table

The CNC ATC woodworking engraving machine is equipped with an automatic tool changer and a vacuum table switch. This advanced technology allows for seamless and efficient carving and engraving of a variety of materials. The vacuum table switch enables users to easily and quickly change between different work pieces, saving time and increasing productivity. The machine is designed with precision and accuracy in mind, providing excellent results for all woodworking and engraving needs. With its state-of-the-art technology and high-quality construction, the CNC woodworking engraving machine is a must-have for any serious woodworking professional.

Conclusion:

In the realm of woodworking, a CNC wood cutting and carving machine stands as a beacon of precision, efficiency, and creativity, offering artisans and craftsmen the tools to bring their visions to life with finesse and mastery. By harnessing the advantages of these machines, woodworkers can embark on a journey of innovation and craftsmanship, creating timeless pieces that resonate with beauty and artistry.

If you are considering incorporating a CNC wood cutting and carving machine into your woodworking endeavors or have specific questions about its capabilities and applications, feel free to share your aspirations, and I shall provide tailored recommendations and insights to guide you on your journey of woodworking excellence.

Leave a Reply

You must be logged in to post a comment.