Wie wartet man die CNC-Schneidemaschine?

This time teach you how to maintain the machine by lubricating the transmission part.

Holzbearbeitung CNC Schneidemaschine is a tool equipment. It has a certain running-in period. During the first three months of use, be careful not to cut too fast, and not to overheat the drive motor for a long time. It is necessary to frequently clean up the impurities and dust on the guide screw bearings and oil them for maintenance.

Note: It is forbidden to wipe the rail rack with a damp cloth. If the rail rack rusts, it is not covered by the manufacturer’s warranty.

Note: It is forbidden to wipe the rail rack with a damp cloth. If the rail rack rusts, it is not covered by the manufacturer’s warranty.

In normal use, the CNC cutting machine should be cleaned of impurities frequently and lubricated with oil. Otherwise, a lot of dust and impurities will enter the screw, guide rail, sliding block and bearing under the long-term operation of the cutting machine. When there is too much dust and impurities, the rotation resistance of the screw, slider, and bearing will increase, and the material will be dislocated if the cutting speed is slightly faster. So how to lubricate the machine?

Lubrication method:

Choose lubricating material: Lubricating oil above No. 40 is not easy to be too thick.

Lubricating parts: x.y.z three-axis track slider, rack and pinion screw bearings.

Lubrication steps: Before lubricating, remove the impurities in the rack, pinion, lead screw, guide rail, and bearing slider. If they cannot be removed, they can be cleaned with gasoline, and then lubricated in lubricating oil and then gradually increase the speed run it. When lubricating, do not put the board for processing.

Lubrication cycle: It depends on the working environment and the working hours of the machine. Generally, the debris is cleaned up after get off work every day. Lubricate all parts every month for high-speed lubrication.

Lubrication method: Use a grease gun to inject lubricating oil into the slider. Use an oil can to drip oil on other parts or wipe the oil with a cloth.

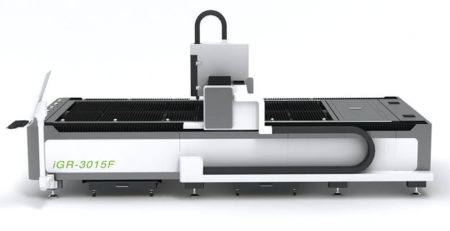

IGOLDEN CNC ist der führende CNC Router Designer, Hersteller und Exporteur seit 2003. Wir haben über 400 professionelle Mitarbeiter und über 70.000 Quadratmeter Fabrik. Unsere hochwertigen, innovativen Produkte umfassen ATC-CNC-Fräsen, CNC-Holz-Tür-Graviermaschinen und Faserlaser-Maschine, etc. OEM und ODM sind verfügbar. Unsere jährliche Produktion von CNC-Maschinen beträgt über 12.000 Sätze, die in über 136 Länder exportiert wurden. Wenn Sie Fragen oder Anfragen haben, füllen Sie bitte das folgende Formular aus und senden Sie es ab. Wir werden Ihnen so schnell wie möglich antworten.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.