Billigste CNC-Maschine für Holzschnitzerei

A CNC machine for wood carving is a computer-controlled tool designed for precision carving, cutting, and shaping of wood materials. These machines are widely used in woodworking, furniture making, cabinetry, and artistic carving for their ability to produce intricate and detailed designs with high accuracy.

Kategorie: CNC-Holz-Fräsmaschine>>ATC CNC-Fräsmaschine

Reaktionszeit: Innerhalb von 1 Stunde

Lieferfähigkeit: 300 Sets/Monat

Preisspanne: $9000-$15000

Beschreibung

CNC-Holzschnitzmaschine

A wood carving cnc machine is a powerful tool that has revolutionized the woodworking industry. Whether you’re a professional carpenter, a hobbyist, or a manufacturer, this machine allows you to carve, engrave, and cut wood with precision and efficiency. Unlike traditional hand tools, a CNC router follows programmed instructions to create intricate designs with minimal effort.

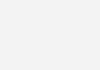

CNC-Holzfräse is a CNC Machine that can do 2D/2.5D/3D routing, cutting, carving, milling, grooving, and drilling on woodworking. They are widely used to making cabinets, wooden doors, wood signs, wood crafts, wood artwork, wood modeling, wood musical instruments, and some wood furniture. If you are a woodworker, craftsman, wood fabricator, CNC wood machinist, DIY enthusiast, or wood carving beginner, then it is worthwhile to invest in a wood router now!

CNC-Holzschnitzmaschine

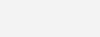

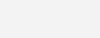

Werkzeugwechslermagazin + 9KW luftgekühlte Spindel

Drehvorrichtung + Schwenkkopf

Key Features of CNC Machines for Wood Carving

- Hohe Präzision:

- Achieves intricate and detailed carvings with tight tolerances.

- Vielseitigkeit:

- Can carve a variety of wood types, including hardwood, softwood, plywood, and MDF.

- Automatisierung:

- Reduces manual labor and increases efficiency by automating the carving process.

- Customizable Designs:

- Allows users to create and replicate complex designs using CAD/CAM software.

- Scalability:

- Suitable for both small-scale projects and large-scale production.

Applications of CNC Wood Carving Machine

Furniture Making: Carving intricate designs and patterns on furniture pieces.

Cabinetry: Creating detailed carvings and engravings on cabinet doors and panels.

Sign Making: Carving letters, logos, and designs on wooden signs.

Art and Sculpture: Creating 3D carvings and artistic designs in wood.

Architectural Elements: Carving decorative elements for buildings, such as moldings and trim.

Custom Woodworking: Producing unique, customized pieces for clients.

Holzfenster aushöhlen

Holzhandwerkliche Prägung

Verarbeitung von Holztüren

Plastisches Schnitzen

Verarbeitung von Holzmöbeln

Bearbeitung von Schranktüren

Holzhandwerk Relief

Schneiden von Acrylglas

CNC Wood Carving Machine FAQ

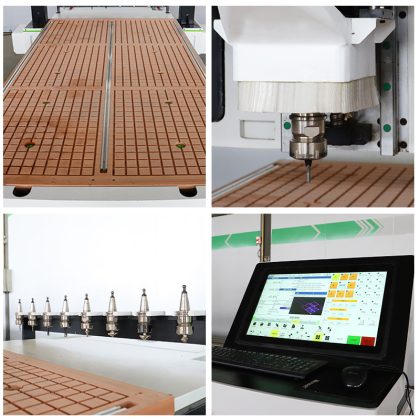

The performance of the CNC wood carving machine depends on all the parts. In fact, it moves like a stream. In the initial step, the operator uses design software to design various patterns that must be done by the cutting tool. If the operator is not able to create complex patterns, they can download a design from the Internet and use the software to convert it to the required format of the machine. The second step is to use control software that allows the operator to control the axes and spindles.

In fact, the operator uses the electrical control panel to give the required coordinates to the machine, and the device determines its final movement according to these coordinates. The command issued by the machine software is executed by the spindle and transmitted to the axes. The axes also move according to the order already specified for them and move the cutting tool in different directions. In fact, the thing about a CNC wood carving machine is that all the commands are defined in the software and electrical control, and the operator is out of the cycle. At this stage, the role of the operator is limited to monitoring the operation of the machine.

The performance of the CNC wood carving machine depends on all the parts. In fact, it moves like a stream. In the initial step, the operator uses design software to design various patterns that must be done by the cutting tool. If the operator is not able to create complex patterns, they can download a design from the Internet and use the software to convert it to the required format of the machine. The second step is to use control software that allows the operator to control the axes and spindles.

How much does a CNC wood router cost? Well, IGOLDENCNC has various CNC wood routers for sale, the price range is $4000 – $30000, and the specific price depends on the machine configurations you choose! Whether you’re looking for affordable wood CNC machines, inexpensive wood CNC machines, or the most expensive CNC routers, feel free to contact your budget and needs, and we will give you the most valuable advice.

- A ridge cutter is suitable for the processing of high-density wood composite board (plywood, particleboard, hard fiberboard, blockboard, etc.) or solid wood (softwood, hardwood, and modified wood).

- A double-edged straight groove milling cutter is suitable to process the multi-layer board and plywood.

- A diamond machining tool is recommended to process the Acrylic mirror sheet.

- A multi-strip milling cutter is perfect for the processing of rough machining particleboard.

- A single-edged spiral ball-end milling cutter is suitable for processing the cork, density board, native wood, PVC board, and acrylic large-scale deep relief.

- A single-blade special aluminum milling cutter is suitable for cutting Aluminum plates.

- A round bottom cutter is recommended to process the meticulous small relief works.

- A single-edged, double-edged up and down cutting cutter is perfect for the burr-free cutting process.

- A double-tool large chip evacuation spiral milling cutter is suitable to cut the MDF board.

- A single-edged spiral milling cutter is perfect for Acrylic cutting.

The performance of the CNC wood carving machine depends on all the parts. In fact, it moves like a stream. In the initial step, the operator uses design software to design various patterns that must be done by the cutting tool. If the operator is not able to create complex patterns, they can download a design from the Internet and use the software to convert it to the required format of the machine. The second step is to use control software that allows the operator to control the axes and spindles.

Making art pieces with the use of hands is very valuable and is highly accepted in the community. But we must admit that traditional wood carving tools and the use of hands in industrial processes and high-volume production do not work well. And also will not have the efficiency desired by activists in this field. For this reason, they turn to use the best CNC wood carving machine. Considering the capacity of these machines and the effect they can have on the production of wood and metal. We will pay attention to the study of the CNC machine and how it works in this section and try to introduce its different parts. So stay tuned!

Verwandte Produkte

Benötigen Sie einen Katalog, einen Preis oder ein Arbeitsvideo der Maschine? Bitte teilen Sie uns Ihren Namen und Ihre E-Mail-Adresse mit, damit wir Ihnen so schnell wie möglich weitere Informationen zusenden können.

Schreibe die erste Rezension für „Cheapest CNC Machine for Wood Carving“

Du musst angemeldet sein, um eine Rezension veröffentlichen zu können.

Rezensionen

Es gibt noch keine Rezensionen.