Laserschneidmaschine für Textilien

A laser cutting machine for textiles is a specialized tool designed for precision cutting, engraving, and marking of fabric materials. widely used in the fashion, apparel, home textiles, and automotive industries for their ability to produce clean, intricate, and high-quality cuts without fraying or damaging the fabric. Below is an overview of laser cutting machines for textiles, including their features, applications, and considerations for choosing the right one.

Laserschneidmaschine für Textilien

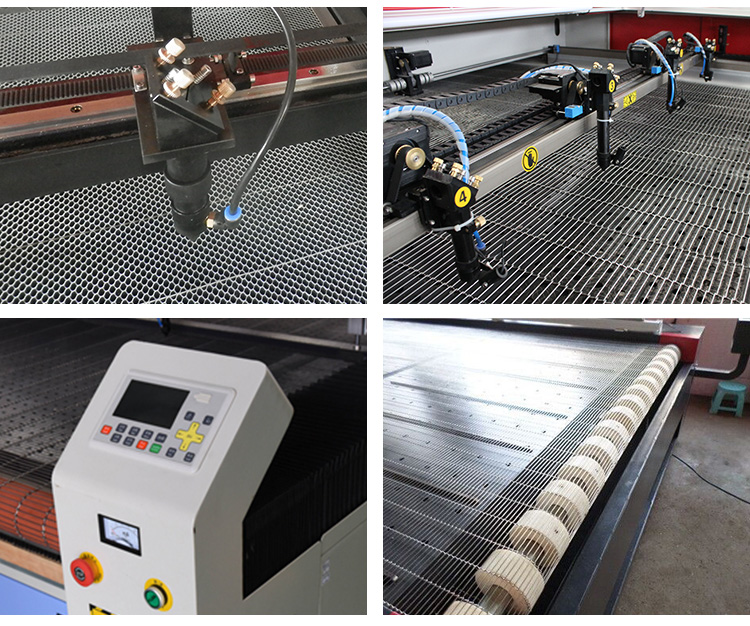

A laser cutting machine for textiles uses a focused laser beam to cut or engrave fabric materials with high precision. The laser vaporizes or melts the material along the cutting path, resulting in clean, sealed edges that prevent fraying. These machines are ideal for cutting a wide range of textiles, including cotton, polyester, silk, leather, felt, and synthetic fabrics.

Fabric laser cutting machine is a type of CO2 laser cutting system with automatic feeder and roller for all kinds of fabrics (silk fabrics, pure cotton fabrics, decorative fabrics, polyester fabrics, chemical fiber fabrics, pure linen fabrics), felts, grey fabrics, dust-free cloth, non-woven fabrics, patch embroidery, leather (leather, artificial leather, decorative leather) , Packaging leather, soft leather) and other clothing accessories and leather materials cutting or engraving.

Features of Textile laser cutting machine:

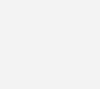

Equipped with a 1600*3000mm working table, which can meet the cutting of large-sized flexible materials

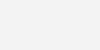

Textile laser cutting machines are suitable for cutting various flexible materials such as leather, denim, plush fabrics and composite materials.

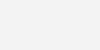

Easy-to-operate and highly scalable fabric laser printing system: The combination of the printing system and laser cutting does not require outputting cardboard patterns, and only needs to modify a small amount of key data to realize the linkage modification of the pattern structure, as well as the left and right shoe shapes. .Image function, can cut left and right feet at the same time. The automatic typesetting function reduces scrap.

Die fabric laser cutting machine is a fully automatic feeding and automatic rolling cutting machine specially developed for the fabric manufacturing industry. Completely replace the ancient perm process, no smoke when working, save materials, the edge of the knife does not burn the edge, no lint when cutting, environmental protection and pollution-free work.

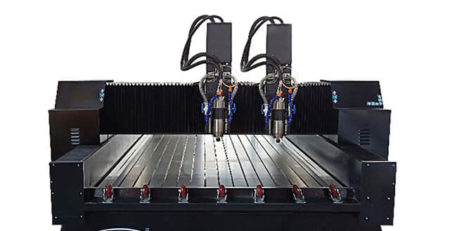

Automatic feeding laser cutting machine

Die textile laser cutting machine adopts Taiwan Shangyin linear motion guide rail to ensure the smooth, high-speed and no jitter of the laser head during operation. It has the characteristics of small slit, fast speed and high precision, which ensures the precision and service life of the equipment.

Automatic typesetting function of cloth laser cutting machine software. After the cutting pattern design is completed, the software automatically typeset, and the material pattern fits closely to reduce waste.

The cloth laser cutting machine breaks the situation of slow speed and difficult typesetting of traditional manual and electric shears, and fully solves the problems of low efficiency and waste of materials. The cutting speed is fast and the operation is simple. Just input the graphics and dimensions to be cut into the computer, and the cutting machine will accurately calculate the cutting machine through the typesetting software. The cutting machine will cut the entire material into the finished product you need, without tools and molds, using lasers to achieve non-contact processing, which is simple and fast, and improves production processing efficiency.

The fabric laser cutting machine is cheap and consumes less, and because the laser processing has no mechanical pressure on the workpiece, the effect, precision and cutting speed of the cut products are very good, the operation is stable, the incision is delicate and clean, and it also has the advantages of safe operation, simple maintenance, etc. advantage. It can work continuously for 24 hours.

Laser Engraving Machine For textile Applications:

Textile laser engraving machine suit for leather, fabric, textile, cardboard, plastic box, fiber glass,corrugated cardboard, sticker, film, foam board,rubber, cloth, gasket material, garment cloth, footwear material, bags materials, non-woven fabrics,seat cover, carpets/rugs, sponge, PU, EVA, XPE, PVC, PP, PE, PTFE, ETFE and composites.

Laser fabric cutter is suitable for cutting all kinds of nylon cloth, polyester cloth, canvas, waterproof cloth, microfiber dust-free cloth and other fabrics, especially suitable for cutting larger size products, such as sports goods, leisure travel goods, etc. It can also be used for processing veneer cut flowers, leather products, acrylic products, etc. The basic principle of the laser fabric cutting system is to use a laser beam with high intensity and concentrated direction as a cutting tool, and use the laser beam to melt the fiber material to realize the cutting operation.

Interessante Fakten zum Laserschneiden von Stoffen und Textilien

Die Verwendung eines Thunder Laser Geräts bedeutet keinen direkten Kontakt mit dem Benutzer und ist daher sicher, im Gegensatz zu einem herkömmlichen Schneidegerät, das scharfe Kanten hat und versehentliche Schnitte verursachen kann. Ein Laserschneider kann effizient ein- oder mehrlagiges Stoffmaterial schneiden. Laserschneider erfordern keinen direkten Kontakt mit dem zu schneidenden Material und verringern so die Möglichkeit, dass dessen Form verzerrt wird, was zu einer sauberen und perfekten Schnittkante führt.

Das manuelle Schneiden mit einem herkömmlichen Messer oder einer Schere kann mühsam und zeitaufwändig sein. Stellen Sie sich vor, in der Produktion eines Textilherstellers kann ein Arbeiter nicht so viel schneiden wie ein CO2-Laser. Mit dem Einsatz einer Laserschneidmaschine wird die Arbeit mit enormer Geschwindigkeit und Präzision erledigt. Erwarten Sie, dass sich die Produktion durch die Laserschneidetechnik verdoppelt oder sogar verdreifacht.

Laserschneidmaschinen benötigen keine zusätzlichen Werkzeuge für die Erstellung von Designs und Mustern auf empfindlichen Stoffen und Textilien. Die Software ist bei den meisten Lasermaschinen im Lieferumfang enthalten und enthält alle Informationen, die Sie für die ersten Schritte benötigen.

Die Laserschneidetechnik ist darauf ausgelegt, Fehler und Mängel während des Laserschneidens zu minimieren. Beim Schneiden von Stoffen mit einem Laser ist Präzision das A und O. Eine Lasermaschine garantiert jedes Mal den gleichen Schnitt, wenn sie richtig programmiert wurde. Der Stoff mit lasergeschnittenem Design weist keinerlei Verfärbungen, Verformungen oder ungleichmäßige Kanten auf.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.