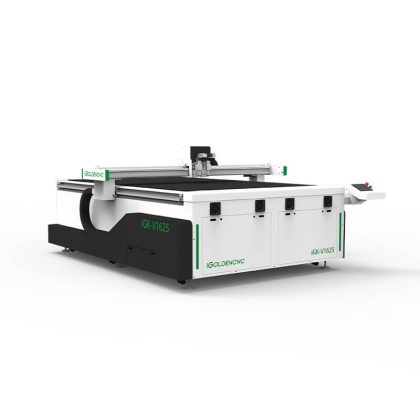

Kohlenstoff-Faser-Glas-Verbundwerkstoff-Schneidemaschine

Cutting and processing carbon fiber glass composite materials presents a unique set of challenges. Traditional cutting methods, such as die cutting or guillotine shearing, can often result in delamination, fraying, or uneven edges, compromising the structural integrity and aesthetics of the final product. This is where the carbon fiber glass composite oscillating knife cutting machine steps in, revolutionizing the way these advanced materials are handled.

Category: Digital Cutting Machine>>Oscillating Knife Cutting Machine

Reaktionszeit: Innerhalb von 1 Stunde

Lieferfähigkeit: 300 Sets/Monat

Preisspanne: $5000-$8000

Beschreibung

Composite Material Cutting Machine

Composite materials, such as carbon fiber, glass fiber, and advanced polymer-based composites, have become increasingly prevalent across a wide range of industries, including aerospace, automotive, marine, and industrial manufacturing. These materials offer a unique combination of strength, lightweight, and customizable properties, making them essential for the production of innovative, high-performance products.

Digital cutting machines offer the precise cuts, high speeds, and automated approach required by many facilities cutting carbon fiber. Automated cutting also offers businesses the ability to customize their cutting machines. For example, IGOLDEN’s tool head can be outfitted with two or three tool spindles from our vast catalog of more than 60 blades, punches, and notches. Dry carbon fiber is often cut with a round knife in order to crush and break the fibers. A 10-sided blade offers strength and versatility for cutting multiaxial carbon fiber cloth. Our ultrasonic tool head, which operates at 20,000 oscillations per second, provides a fast, accurate cut while reducing gumming and friction when cutting adhesive-backed composites.

CNC Digital Knife Cutting Machine Anmeldung

CNC Cutting machines are specially designed for soft material cutting. It is especially good for foam, glass fiber, carbon fiber, prepreg, gasket cutting. It has been widely used in areas as advertisement, packing, decoration, cloth, shoes, furniture,etc.

Digital Composite Material Cutting Machine

Used for cutting leather, gasket, PP, PE, EVA, PTFE, ETFE, carpet, carton, wood, MDF, PVC, acrylic, cardboard, rubber, corrugated carton, foam, leather, composite materials, cardboard, corrugated board, honeycomb paper, plastic film, fiber paper, plastic box, resilient glue, rubber cloth, etc.

Key Considerations for Selecting the Optimal Oscillating Knife Cutting Machine

When integrating a carbon fiber glass composite oscillating knife cutting machine into your manufacturing operations, there are several critical factors to consider:

- Material Compatibility: Ensure that the cutting machine is designed to handle the specific composite materials you work with, considering factors such as thickness, density, and fiber orientation.

- Cutting Precision and Quality: Prioritize machines that offer the highest levels of cutting precision and the ability to produce clean, consistent edges on the composite components.

- Automation and Workflow Integration: Look for oscillating knife cutting machines that seamlessly integrate with your existing production workflows, including material handling systems and digital design software.

- Sicherheit und ergonomische Merkmale: Bewerten Sie die Sicherheitsmechanismen und das ergonomische Design der Maschine, um Ihre Mitarbeiter zu schützen und die allgemeine Zufriedenheit am Arbeitsplatz zu erhöhen.

- Scalability and Future-Proofing: Consider the growth trajectory of your business and select an oscillating knife cutting machine that can scale to accommodate your evolving composite material processing needs.

Related products

Elevating Your Composite Material Processing with Oscillating Knife Cutting Technology

By integrating a state-of-the-art carbon fiber glass composite oscillating knife cutting machine into your manufacturing operations, you can unlock a new era of precision, efficiency, and competitiveness. This strategic investment empowers you to:

- Streamline your composite material cutting workflows and enhance overall throughput.

- Achieve unparalleled consistency and quality in the finished composite components.

- Diversify your product offerings and cater to a wider range of customer needs.

- Reduce material waste, energy consumption, and environmental impact

- Enhance workplace safety and improve operator satisfaction.

Benötigen Sie einen Katalog, einen Preis oder ein Arbeitsvideo der Maschine?

Bitte teilen Sie uns Ihren Namen und Ihre E-Mail-Adresse mit, damit wir Ihnen so schnell wie möglich weitere Informationen zusenden können.

Schreibe die erste Rezension für „Carbon Fiber Glass Composite Material Cutting Machine“

Du musst angemeldet sein, um eine Rezension veröffentlichen zu können.

Rezensionen

Es gibt noch keine Rezensionen.