CNC-Schneidemaschine_Dreiprozess-CNC-Schneidemaschine

As the application of CNC-Schneidemaschine becomes more and more extensive, it is one of the main equipments in the production of panel furniture. The quality of its equipment directly affects the quality of the product, and what effect does it have on the precision of the CNC cutting machine?

Position. The initial cutting tool is a table saw. The positioning of the table saw is manually determined by the substrate on the table saw. The strength and angle of the hand can only be controlled by feeling, and the processing accuracy is not high. The matching CNC cutting machine relies on the positioning cylinders to be positioned at right angles to each other, which ensures the processing accuracy from two aspects. Then push the cylinder and the two cylinders on the feeder into a right angle with the positioning cylinder, so as to increase the processing accuracy. There is another one here is that when the material is opened, a flap is required. The accuracy of the front and rear flaps is guaranteed by the cooperation of the positioning cylinder, the column and the cylinder on the feeding device, and the effect on the plate is the same twice before and after. Yes, which also guarantees the precision of machining.

Position. The initial cutting tool is a table saw. The positioning of the table saw is manually determined by the substrate on the table saw. The strength and angle of the hand can only be controlled by feeling, and the processing accuracy is not high. The matching CNC cutting machine relies on the positioning cylinders to be positioned at right angles to each other, which ensures the processing accuracy from two aspects. Then push the cylinder and the two cylinders on the feeder into a right angle with the positioning cylinder, so as to increase the processing accuracy. There is another one here is that when the material is opened, a flap is required. The accuracy of the front and rear flaps is guaranteed by the cooperation of the positioning cylinder, the column and the cylinder on the feeding device, and the effect on the plate is the same twice before and after. Yes, which also guarantees the precision of machining.

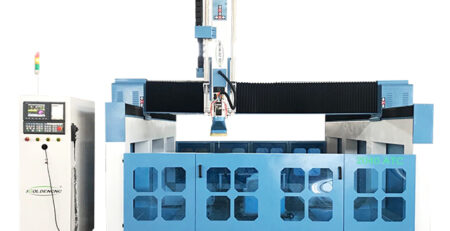

Dreiprozess-CNC-Schneidemaschine

guide. A large part of the reason for the base of the CNC cutting machine is due to the function of the guide rail. It is necessary to check the wear of the copper wheel. The grinding operation of the copper wheel is not stable, which affects the cutting accuracy.

Flatness. The flatness of the circular saw table is the main reason that affects the machining accuracy. This problem is mostly ignored. The saw table of the new equipment looks relatively flat. After a long time, the countertop will be under a lot of pressure. Therefore, the stability of the sawing machine will affect the cutting effect for a long time. It should be noted here that if the compression deformation of the body affects the cutting accuracy, the solution is to replace the equipment.

knives. When the cutting tool is used for comminution cutting of the plate, the cutting tool becomes a direct influencing factor. The blade is worn, that is, every few blades need to be repaired or replaced. At this time, it is necessary to modify the tool compensation according to the diameter of the tool, so it is recommended that you choose a tool with better quality, which can also ensure the machining accuracy.

A good equipment is not as simple as we imagined. Hundreds of accessories go through a strict production process. Every step must be carefully and strictly inspected before it can officially leave the factory. This is why the construction period is long and the price is high. reason for the high. Friends who are accustomed to the configuration higher than the price ignore these steps that affect the quality of the equipment. The editor of Jiabang CNC reminds the majority of friends again that the purchase of equipment should choose a large manufacturer, and do not be greedy for cheap.

Recommended equipment: three-process CNC cutting machine

The bed of the three-process CNC cutting machine is processed by large-scale gantry milling, high-temperature tempering and quenching, and a segmented rectangular tube welding bed is welded by a plurality of rectangular tubes with a thickness of 6mm. . The column and the bed are assembled on the side, and the equipment runs more smoothly; the five-axis machining center mills the connecting reference plane and drills at one time to ensure product accuracy.

Merkmale:

Sparen Sie Arbeit Auch wenn es nur eine Person gibt, können Entwurf, Satz, Laden, Produktion und Entladen abgeschlossen werden. Eine Person kann mehrere Geräte bedienen, die Arbeitseffizienz verbessern und eine Menge Arbeitskosten sparen.

Sparen Sie sich die automatische Aufteilung und den automatischen Satz von Platten, verbessern Sie die Auslastung der Platten und helfen Sie den Unternehmen, die Produktionskosten zu senken.

Ein Gerät mit vielen Funktionen und vollständiger Konfiguration, Gravieren, Schneiden, Aushöhlen, Stanzen und Nuten, kann mehrere Prozesse verarbeiten.

Hohe Verarbeitungseffizienz, hohe Geschwindigkeit, hohe Leistung, genaue Präzision, weniger Abfall, Automatisierung, niedrige Kosten, weniger Staub, gute Umweltbedingungen, hohe Effizienz und Umweltschutz sind derzeit die wichtigsten Aspekte.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.