China Handgehaltene Faser-Laser-Schweißmaschine

Wie viel kostet ein Laser-Schweißmaschine? This question is something we need to consider when choosing welding equipment, but it is not the main reason. Why did you say that? Anyone who has purchased or used laser equipment knows that the real value of laser welding equipment is whether it is suitable and meets their welding requirements. For example, if I give you a laser welding equipment with hundreds of thousands of dollars, but it is not suitable for your product, it is useless. Therefore, when consulting the price of laser welding equipment, laser equipment manufacturers will generally ask you about your welding needs, or directly ask you to proof and see the effect before quoting. Therefore, it is not to say that the more expensive the laser equipment, the better, but to choose the one that suits you, or choose the best configuration within your acceptable range. Follow the editor of Jiabang Laser to find out what are the factors that affect the price of laser welding equipment?

The price of laser welding machine, laser welding machine has the advantages of simple operation, beautiful welding seam, fast welding speed, and no consumables. It can perfectly replace traditional argon arc welding, electric welding and other processes. The prices of laser welding machines on the market today vary widely. Even for the same model of welding machine, the price of different manufacturers will be different. Jiabang Laser is a laser equipment manufacturer integrating R&D, production, sales and service of laser equipment. We can customize laser equipment with different powers according to the actual needs of customers. We can also customize the model of laser welding equipment according to customer needs, and the price is also different according to different handheld laser power prices.

Laserschweißmaschine normal price:

Generally speaking, the price range of a 500W Laser-Schweißmaschine should be: 80,000-150,000. Of course, there are also cheap ones, because each manufacturer has different production processes and different materials, so there is a certain gap in price. of.

The price of a 1000W laser welding machine should be between 100,000 and 180,000. Manufacturers produce various types of laser welding machines according to the different needs of users. Naturally, the prices are also different.

The price of a 15 million laser welding machine is between 120,000 and 200,000. In addition, there are 20 million laser welding machines, which customers can choose according to their needs.

Factors affecting the price of handheld laser welding:

Whether the price of the laser welding machine is reasonable in terms of quality. As we all know, the price of laser welding machine should be proportional to the quality. The better the quality, the more expensive the price. If other factors are the same, the quality is not good but the price is expensive, the price of this laser welding machine is unreasonable. .

from the manufacturer’s point of view. The reputation and reputation of the manufacturer itself also affects the price of the final laser welding machine. The price of laser welding machine with high reputation and good reputation will be slightly more expensive.

From an after-sales perspective. After-sales service of laser welding machine manufacturers is very important. Responsible after-sales can help users solve most of their troubles, one-stop service, professionals can help guide and solve problems. It can be said that professional after-sales can save users a lot of money and time.

The above is a brief introduction to the price of Laser-Schweißmaschine and its impact on price. More and more price dealers and factories choose laser welding machines mainly considering handheld, better flexibility, fiber laser welding, better performance than other welding, and lower labor costs, so the initial investment in purchasing a laser welding machine is relatively large, but In the long run, production costs are still available. Customers can choose suitable handheld laser welding equipment according to their own situation.

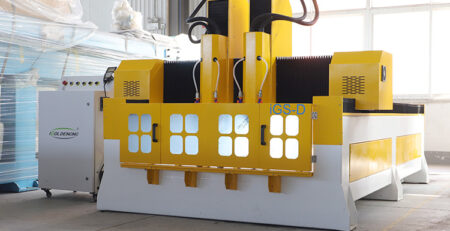

Industrie Laser welding machine application

Handgehaltene Laserschweißmaschine, mit Infrarot-Präzisionspositionierung, flexibel und bequem, festes Schweißen, keine Verbrauchsmaterialien, glatte und feine Schweißnaht und nicht leicht zu verformen, vor allem für das Laserschweißen von langen und großen Werkstücken, weit verbreitet in großen und mittelgroßen Blechen, Schränken und Fahrgestellen, Langstrecken-Punktschweißen, Vollschweißen, kontinuierliches Schweißen, Dichtungsschweißen von inneren Ecken, äußeren Ecken und Nähten von großen Werkstücken wie Aluminium-Legierung Tür- und Fensterrahmen, Treppen, Aufzüge und Edelstahlmöbel.

Laserschweißen kann zum Schweißen von Titan, Nickel, Zinn, Zink, Kupfer, Aluminium, Chrom, Niob, Gold, Silber und anderen Metallen und deren Legierungen sowie von Stahl, Kovar und anderen Legierungen aus demselben Material eingesetzt werden. Es kann zum Schweißen verschiedener ungleicher Metalle wie Kupfer-Nickel, Nickel-Titan, Kupfer-Titan, Titan-Molybdän, Messing-Kupfer und kohlenstoffarmer Stahl-Kupfer eingesetzt werden. Gleichzeitig ist es auch in Branchen wie der Mobiltelefon-Kommunikation, elektronischen Komponenten, Brillen und Uhren, Schmuck, Hardware-Produkten, Präzisionsgeräten, medizinischen Geräten, Autoteilen und handwerklichen Geschenken weit verbreitet.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.