Automatische CNC-Schneidemaschine_Scheibenwerkzeugwechsel-Bearbeitungszentrum plus Reihenbohrmaschine

Gegenwärtig, automatische CNC-Schneidemaschine is getting more and more hot in the market. It differs in the treatment of its invisible parts. The non-porous process invisible connector is used for furniture processing, with beautiful appearance, good stability and easy installation. Now more and more invisible connectors are used in the non-porous process, and the later cost will be cheaper and cheaper. And this device is not only used as an invisible part, but also can realize traditional three-in-one and wood carving.

Automatic CNC cutting machine is a special machine for cutting and grooving custom panel furniture. It gets rid of the traditional cutting method, reduces labor, and realizes intelligent production combined with the design of disassembly and typesetting software. Many businesses struggle with choosing equipment. What kind of machine should they choose? Today, Jiabang CNC will show you the difference between automatic CNC cutting machine and ordinary CNC cutting machine.

Automatic CNC cutting machine is a special machine for cutting and grooving custom panel furniture. It gets rid of the traditional cutting method, reduces labor, and realizes intelligent production combined with the design of disassembly and typesetting software. Many businesses struggle with choosing equipment. What kind of machine should they choose? Today, Jiabang CNC will show you the difference between automatic CNC cutting machine and ordinary CNC cutting machine.

Compared with general CNC-Schneidemaschine, the advantages of automatische CNC-Schneidemaschine technology:

In terms of machine tool function, automatic CNC cutting machine has more functions than general cutting machine, and the process to be solved is complicated.

Assembly: The automatic CNC cutting machine is difficult to assemble, requires high assembly requirements, and has high inspection standards.

In terms of machine configuration: since the automatic CNC cutting machine is a saw blade spindle added on the basis of the woodworking center, the configuration of the woodworking center itself is higher than that of the automatic numerical control cutting machine, so the configuration of the automatic numerical control cutting machine is slightly higher than that of the automatic numerical control cutting machine. Ordinary cutting machine.

In terms of machine price: the automatic CNC cutting machine is at least 30,000 to 40,000 higher than the ordinary cutting machine.

In the learning and operation of the machine: the automatic CNC cutting machine needs to learn a little more operating technical points than the ordinary cutting machine.

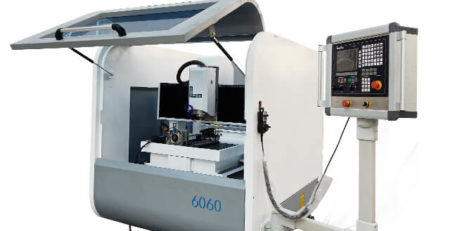

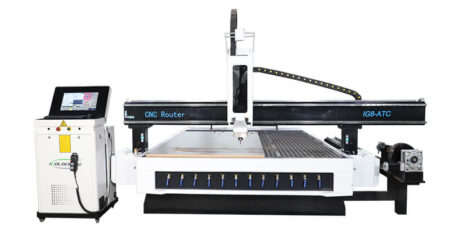

Recommended equipment: disc tool changer machining center plus row drill

Features of disc tool change machining center with drill row:

Optimierte Schneiden, Stanzen, Nuten, und perfekte Kombination, ist der Prozess ununterbrochen, um die Effizienz und Leistung zu maximieren, und die starke Kompatibilität kann nahtlos mit einer Vielzahl von um Demontage-Software verbunden werden;

Durch die modulare Bauweise können Sie drei modulare Einheiten wählen: Einzelspindel + CNC-Bohrpaket, Doppelspindel + CNC-Bohrpaket, automatische Werkzeugwechselspindel des Scheibenwerkzeugmagazins + CNC-Bohrpaket;

Adopt 200×250 dickwandigen Vierkantrohr Halterung Struktur, Engineering ästhetisches Erscheinungsbild Design Struktur, Härten oder Vibrationen Vektor-Effekt Behandlung, importiert Pentaeder Metallbearbeitungszentrum für hochpräzise Fräsen;

Es nimmt seitlich montiert Typ, 3 Flansch Schieber auf einer Seite Design-Struktur, stabilen Betrieb, voll staubdicht Design Struktur der Rack-Führungsschiene, Führungsschiene nimmt segmentierte Struktur, und der Austausch der Führungsschiene erfordert keine Fachleute, die mehr bequem ist;

Numerical control system, stable performance, simple operation, ordinary people can complete the operation after simple training without professional knowledge;

The double-layer hollow vacuum adsorption table is adopted, which can adsorb plates of different sizes, and the minimum opening plate can reach 25mm;

The four-direction, six-action plate automatic positioning system is adopted, the plate positioning is faster and more accurate, and the automatic detection system of the plate feeding position is matched, which can effectively prevent various unexpected situations that may occur during the plate feeding process;

Matching the central intelligent dust removal system can ensure the effective cleaning and collection of the particulate waste in all links and parts, and can effectively ensure the continuity of the cutting work;

Equipped with a central automatic lubricating system, set to automatically inject oil at regular intervals to ensure the efficient operation of the machine

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.