Die beste Laserschneidmaschine der Welt

Shandong IGOLDEN CNC Technology Co., Ltd, is a comprehensive corporation integrating laser & CNC technology research and development, equipment manufacturing, sales and after-sales, intelligent medical furniture production, foreign trade import and export, park management services and e-commerce. The Group’s brands include IGOLDENCNC, IGOLDENLASER, ZIGUICNC, ZIGUILASER, INEWLASER, IGOLDENOF, etc., products cover many fields such as intelligent medical furniture, industrial laser machine, CNC router machine, panel furniture production line, solid wood furniture production line, plasma cutting equipment and supporting application equipment. Group now has more than 500 employees at domestic and abroad, has enjoyed more than 10 independent brands, and has built a sound sales channel and service network worldwide relying on e-commerce and digital marketing.

Metal tube/pipe Laser Cutting Machine

The tube laser cutting machine is a laser cutting machine specially designed for tube cutting. It can cut round tubes, square tubes, oval tubes, rectangular tubes and irregular tubes. It is equipped with a special cutting operating system, which is simple to operate, high precision and professional. Strong, suitable for professional profile cutting, widely used in sports equipment, petroleum pipelines, chemical equipment and other industries. It can cut carbon steel and stainless steel.

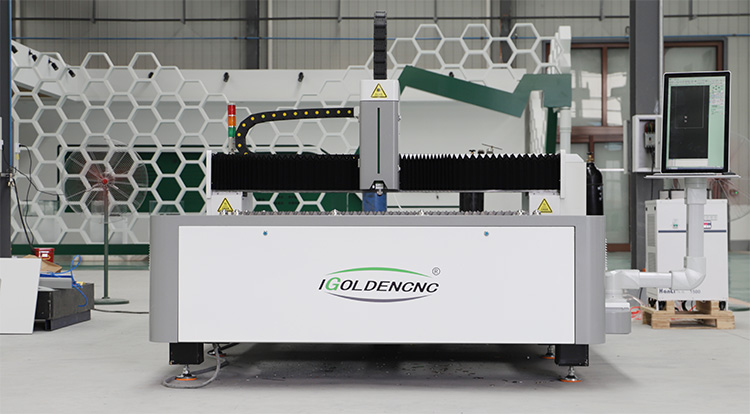

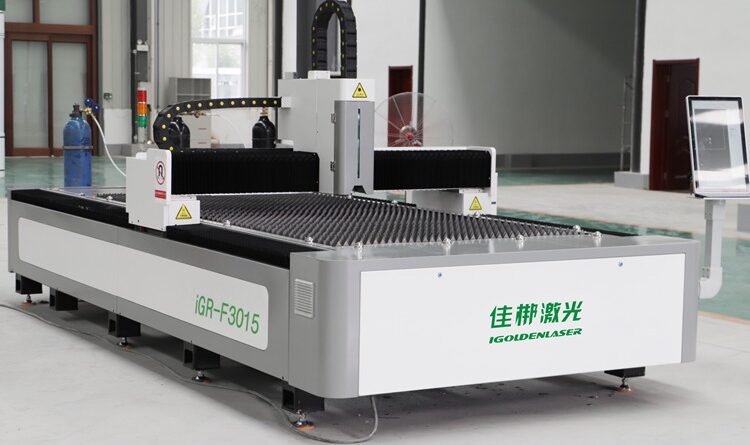

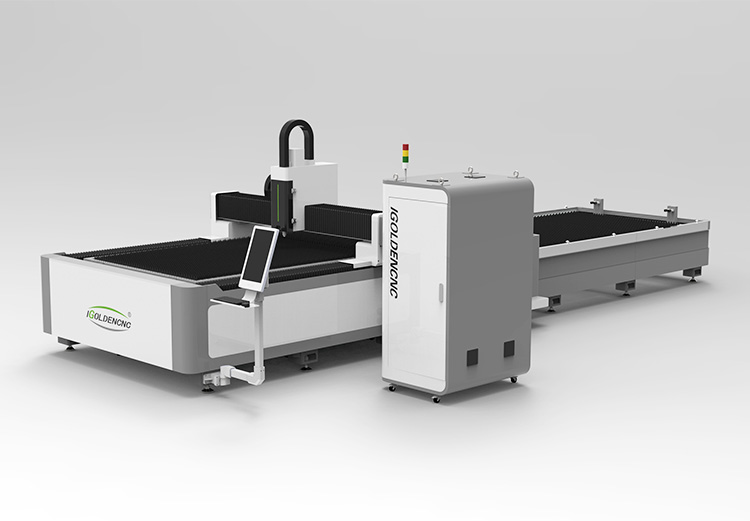

Flatbed Fiber Laser Cutting Machine iGR-F

Fiber Laser Tube Cutting Machine

Metall Rohrlaserschneidmaschine can be used to cut all kinds of metal shapes such as round tubes, square tubes, and special-shaped tubes. The newly upgraded metal pipe laser cutting machine production equipment not only achieves automatic production and processing, but also improves the limitations of traditional laser cutting, saving time and effort, reducing costs, faster and more accurate, and can achieve pipe punching and cutting。

The fiber laser pipe cutting machine is designed to be a comprehensive CNC laser tube cutting machine solution. With a wide range of features and capabilities, this tube cutting laser system is designed to allow users a great degree of tube forming flexibility.

Auto-focus Laser Cutting Head

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position within 20mm. The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials. The compound lens group equipped with D28 integrates the light beam and optimizes the optical and water-cooled design so that the laser head can work stably for a long time.

Autofocus saves focusing time and improves work efficiency by 10 times.

Extend service life, by optimizing the structural design of the cutting head, extend its service life.

Heavy-duty Welding Bed

The heavy-duty welding bed is welded with a thick rectangular tube with a diameter of 200*200mm. The bed weight can reach 1000kg. The bed body is annealed and milled by a large gantry to accurately drill all installation basic holes at once.

Higher tensile strength and dimensional stability. Effectively improve the accuracy of the bed, reduce the processing error of the workpiece. Increase the resistance and stability of the guide rail.

It reduces the loss of the equipment when it is used and keeps the precision of the machine for a long time and does not deform for 20 years. The equipment has good stability and reduces the processing errors caused by the vibration of the bed.

Aero-aluminum Integrated Beam

High precision. After manual aging, solution treatment and finishing, the beam has good integrity, rigidity, toughness and ductility.

Fast speed. Aluminum alloy has the features of lightweight and strong rigidity, which is conducive to high-speed movement during processing, and high flexibility is conducive to the high-speed cutting of various graphics on the basis of high precision.

High efficiency. The lighter weight beam can ensure the rapid operation of the equipment, improve the processing efficiency, and at the same time ensure the processing quality. Not only can the high-speed operation of the laser cutting machine be guaranteed, but also the accuracy and efficiency of the cutting processing.

Effectively improve the service life and accuracy of the laser cutting machine, reduce time cost and reduce time loss. And after using the same time limit, the aluminum beam can ensure the cutting accuracy to the greatest extent, and at the same time, it can alleviate the kinetic energy of laser head during high-speed movement.

IGOLDENLASER ist ein professioneller Anbieter von Laseranwendungen, der Forschung und Entwicklung, Produktion, Vertrieb und Kundendienst integriert und mehr als 8.000 Kunden in aller Welt maßgeschneiderte Lösungen für die Metallbearbeitung anbietet.

Die Produkte umfassen intelligente flexible Laserproduktionslinien, Faserlaserschneidmaschinen, Faserlaserreinigungsmaschinen, Faserlaserschweißmaschinen, Glaslaserbohr- und -schneidemaschinen, Plasmaschneidmaschinen, CO2-Lasergraviermaschinen, Lasermarkiermaschinen usw.

Wir verkaufen Lösungen, die einen größeren Wert für unsere Kunden schaffen.

Auftrag des Unternehmens

IGOLDENLASER hat es sich zur Aufgabe gemacht, den Kunden in der metallverarbeitenden Industrie effizientere, wirtschaftlichere und wertvollere intelligente Gesamtlösungen für die Fertigung zu bieten.

Mit Blick auf die zukünftige Entwicklung des Metallverarbeitungsmarktes hat IGOLDENLASER seine Pläne in drei Hauptrichtungen entwickelt: Intelligenz/Digitalisierung, intelligente Fabriken und grüne Energieeinsparung und Umweltschutz. Mit der Einführung neuer Produkte und der erstaunlichen Wachstumsrate wird IGOLDENLASER auch weiterhin Produkte und Dienstleistungen anbieten, die die Erwartungen der Kunden erfüllen, und zwar für jeden Kunden.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.