Faserschneidemaschine mit Rotation-IGOLDENCNC

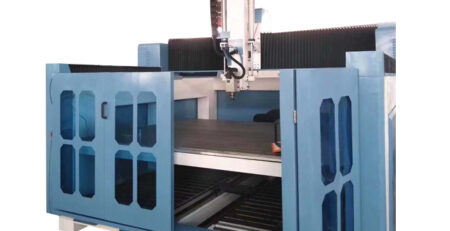

Was ist die Faserschneidemaschine mit Rotation?

Doppelnutzung Faserschneidemaschine mit Rotationausgestattet mit 1000w-6000w Faserlaser, kann 0-25mm dicke Kohlenstoffstahlplatte, 0-20mm dicke Edelstahlplatte und Aluminiumplatte, 0-12mm dicke Kupferplatte und Metallrohr mit 20-200mm Durchmesser schneiden, Standard-Arbeitsbereich ist 1500*3000mm, kann auf 1500*4500mm aufgerüstet werden, die Länge der Rohrschneidteile kann optional 3m, 6m, 9m sein. Es ist ein unabhängiges Kabinett mit eingebauter Klimaanlage für 2000w und mehr Leistung, und kann mit einer seitlichen Rotationsvorrichtung installiert werden, um die Multi-Fuktions-Maschine aufzurüsten, die sowohl Metallplatte und Rohr schneiden kann.

Product Features

- Automatic Lubrication

With automatic lubrication system, it provides the lubrication at regular intervals and extends the life of the transmission mechanism.

- Thick Steel Welding Bed

8~12mm thickness steel welding machine bed instable strcture, it can relase the internal stress by welding after high temperature annealing treatment

- Gantry-Struktur

Stable dual transmission system, high tensity follow-up moudle of cutting head to prevent from crashing on metal sheet, ensure the machine can running safely.

- Material Saving

Apply to standard metal sheet cutting, it will help to save time and material.

Vorteile

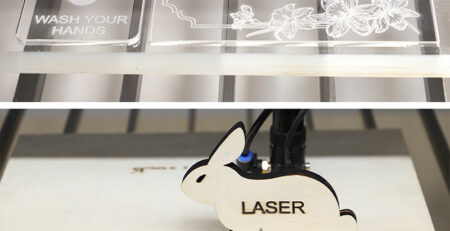

- Excellent beam quality: the focusing light board is smaller, the cutting lines are finer, the work efficiency is higher, and

the processing quality is better.

- Fast cutting speed: The cutting speed is 2-3.5 times that of the same power CO2 laser cutting machine.

- Stable operation: The world’s top imported fiber lasers such as IPG/Raycus/MAX are used, with stable performance, and key components can reach 100,000 hours;

- Very low maintenance cost: no laser working gas; optical fiber transmission, no need for reflective lenses; it can save a lot of maintenance costs.

- Low cost: low power consumption, only about 20%-30% of thetraditional CO2 laser cutting machine, reducing production costs and making you profit faster.

- Simple operation: optical fiberline transmission, no need to adjust the optical path, automatic focus without manual adjustment.

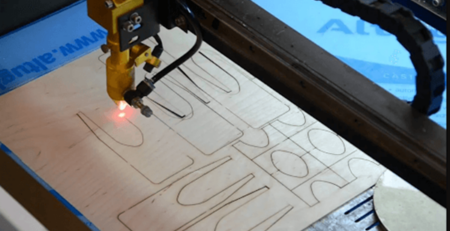

Main application industry

Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, machinery,precision parts, ships, metallurgical equipment, elevators, household appliances, gift crafts, tool processing, decorations,advertising, metal external processing, etc. Kind of manufacturing industry.

Mainly used for cutting low carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel plate,

pickling plate, aluminum zinc plate, copper and various metal materials.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.