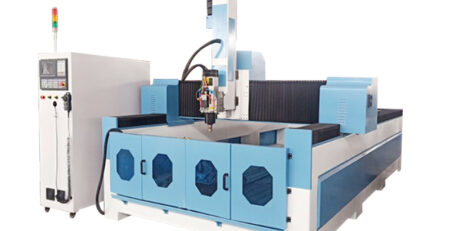

Faserlaserschneidmaschine zum Verkauf

Fiber laser cutting machine is a type of laser cutting system that uses a fiber laser as its energy source. It is widely used in industrial applications for precision cutting of various materials, including metals, plastics, and composites.

Was ist die Faserlaserschneidmaschine?

- Laser Technology: Fiber lasers use a solid-state laser technology in which the active medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, or neodymium. This design offers several advantages over other laser types, including high efficiency, excellent beam quality, and long-lasting performance.

- Cutting Principle: Fiber laser cutting machines work by directing a high-powered laser beam onto the material to be cut. The laser beam is focused through a lens, creating a small, intense spot on the surface. The energy from the laser melts or vaporizes the material at the focal point, while a gas jet blows away the molten or vaporized material, creating a cut.

Faserlaserschneidmaschine is designed for cutting thin metals less than 2mm aluminum, 3mm stainless steel, 4mm stainless steel, 12mm carbon steel and copper, brass, etc, now the affordable stainless steel laser cutter for sale at a low price.

Flatbed fiber laser cutting machine, equipped with 1000w-12000w fiber laser, can cut 0-25mm thick carbon steel plate, 0-20mm thick stainless steel plate, aluminum plate, 0-12mm thick copper plate, standard working area is 1500*3000mm, can be upgraded It is an independent cabinet with built-in air conditioner for 1500*4500mm, 2000w and above power, and can be installed with a side rotation device to upgrade to a dual-use fiber laser cutting machine.

Merkmal

- Economical fiber laser cutter for small factory enter-in.

- Compact structure, small floor area.

- High precision serve motors, lead screws and guide ways with famous brands to ensure the efficiency and accuracy, greatly increasing the stability and reliability.

- It can be equipped with CO2 laser cutting head for non-metal materials cutting, such as wood, acrylic, MDF, etc.

Vorteile der Maschine

AUTOMATISCHES SCHMIERSYSTEM

Das automatische Schmiersystem versorgt die Anlage mit einer festen Menge an Schmieröl, um den Hochgeschwindigkeitsbetrieb des Flachbett-Laserschneiders zu gewährleisten, und verfügt über Alarmfunktionen für abnormale Zustände und Flüssigkeitsstände. Das System verbessert die Schneidgenauigkeit erheblich und verlängert effektiv die Lebensdauer des Getriebemechanismus.

INTELLIGENTES ALARMSYSTEM

Intelligente Reise-Schutz, die automatische Überwachung der Betriebsbereich von Komponenten, die Installation von internationalen Werkzeugmaschinen-Standard-End-Federn, die Laser-Schneidkopf ist eingebaut Kondensator Höhenverstellung Funktion, Kollision zu stoppen, die Verbesserung der Ausrüstung und das Leben Sicherheit Schutz, die Verringerung der Häufigkeit von Unfällen, Verbesserung der Effizienz Schneiden.

SICHERHEITSSYSTEM

Automatische Alarmfunktion für abnorme Arbeitsstatus der Ausrüstung, und schieben Sie es auf die Operation-Schnittstelle durch das Kontrollzentrum, verbessern die Effizienz der Flachbett-Laser-Schneidemaschine abnorme Fehlersuche, reduzieren potenzielle Sicherheitsrisiken, und reduzieren die Wartungskosten.

Transmission and Precision

Germany German Tech Quality

G·WEIKE fiber laser cutting machine is equipped with Taiwan YYC rack, Japanese Yaskawa motor and French Motoreducer. The repeat positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to 10 years.

Anwendungen

3015 fiber laser cutting machine as one classic model, widely used in life, such as processing of stainless steel kitchenware, storage cabinet and other cabinets, is closely related to people’s daily life.

Verwendet für das Schneiden einer Vielzahl von Metallplatten, vor allem in Edelstahl, Kohlenstoffstahl, verzinktem Blech, elektrolytische Platte, Messing, Aluminium, verschiedene Legierung Platte, seltenes Metall und anderen metallischen Werkstoffen verwendet.

Fiber laser cutting machines find applications in various industries, including automotive, aerospace, electronics, sheet metal fabrication, signage, jewelry, medical device manufacturing, and more. They are used for cutting components, parts, prototypes, and intricate designs.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.