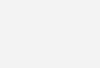

Flachbett-Laser-Metallschneidemaschine zu verkaufen

Was ist die Flachbett-Laser-Metallschneidemaschine?

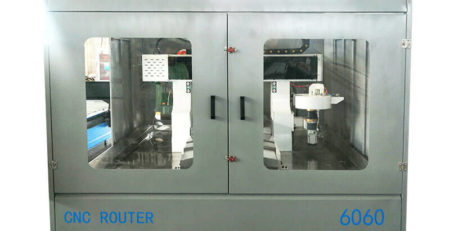

A flatbed laser metal cutting machine is a type of laser cutting machine that is designed to cut flat sheet metal materials. The machine is equipped with a flatbed or table on which the sheet metal material is placed for cutting.

Flatbed laser metal cutting machines are commonly used in various industries, including automotive, aerospace, electronics, and construction, among others. They offer several advantages over traditional cutting methods, including faster processing times, greater accuracy, and reduced material waste. Flatbed laser metal cutting machines can cut a wide range of flat sheet metal materials, including steel, aluminum, brass, copper, and other alloys, making them a versatile and efficient cutting solution for many applications.

Vorteil der Flatbed Laser Cutting Machine

- Versatility: Flatbed laser metal cutting machines can cut a wide range of flat sheet metal materials, including steel, aluminum, brass, copper, and other alloys. They can also cut a variety of thicknesses, from thin sheet metal to heavy plate.

- Precision: Flatbed laser metal cutting machines offer high precision cutting, with excellent accuracy and repeatability. They can cut complex shapes and intricate designs with ease, and can produce very fine cuts with minimal material distortion.

- Efficiency: Flatbed laser metal cutting machines are highly efficient, with fast processing times and high cutting speeds. They can also be automated and integrated with other manufacturing processes, such as bending, forming, and welding, for a complete production solution.

- Low maintenance: Flatbed laser metal cutting machines require minimal maintenance, as they have no physical contact with the material being cut. This reduces the need for tool replacement, sharpening, or other maintenance tasks typically associated with traditional cutting methods.

- Environmentally friendly: Flatbed laser metal cutting machines are an environmentally friendly cutting solution, as they produce minimal waste and emissions. They also use less energy compared to other cutting methods, reducing overall energy consumption and costs.

A flatbed cnc-laser-metallschneidemaschine is a type of equipment that utilizes a laser beam to precisely cut and shape metal sheets or plates. It consists of a flat surface where the metal workpiece is placed and a laser head that moves across the surface, directing the laser beam to cut through the metal material. This type of machine is commonly used in industrial settings for various applications such as fabrication, manufacturing, and metalworking processes.

Merkmal der Flatbed Laser Metal Cutting

AUTOMATISCHES SCHMIERSYSTEM

Das automatische Schmiersystem versorgt die Anlage mit einer festen Menge an Schmieröl, um den Hochgeschwindigkeitsbetrieb des Flachbett-Laserschneiders zu gewährleisten, und verfügt über Alarmfunktionen für abnormale Zustände und Flüssigkeitsstände. Das System verbessert die Schneidgenauigkeit erheblich und verlängert effektiv die Lebensdauer des Getriebemechanismus.

INTELLIGENTES ALARMSYSTEM

Intelligente Reise-Schutz, die automatische Überwachung der Betriebsbereich von Komponenten, die Installation von internationalen Werkzeugmaschinen-Standard-End-Federn, die Laser-Schneidkopf ist eingebaut Kondensator Höhenverstellung Funktion, Kollision zu stoppen, die Verbesserung der Ausrüstung und das Leben Sicherheit Schutz, die Verringerung der Häufigkeit von Unfällen, Verbesserung der Effizienz Schneiden.

SICHERHEITSSYSTEM

Automatische Alarmfunktion für abnorme Arbeitsstatus der Ausrüstung, und schieben Sie es auf die Operation-Schnittstelle durch das Kontrollzentrum, verbessern die Effizienz der Flachbett-Laser-Schneidemaschine abnorme Fehlersuche, reduzieren potenzielle Sicherheitsrisiken, und reduzieren die Wartungskosten.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.