Wie wartet man eine Plasmaschneidmaschine?

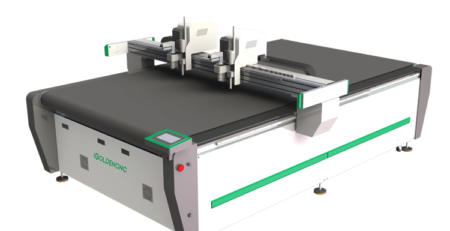

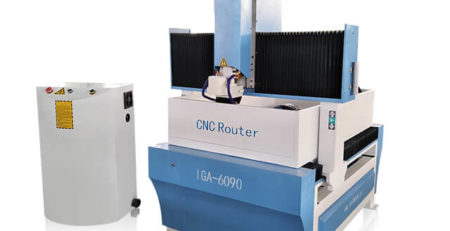

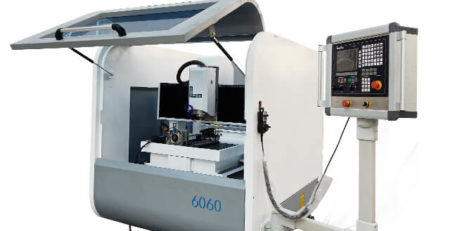

CNC-Plasmaschneidmaschine is an automatic cutting equipment, suitable for cutting and perforating various non-ferrous metal sheets such as carbon steel, stainless steel, iron, aluminum, white steel, etc. Standard plasma cutting and flame cutting modes, integrated structure, bilateral drive, fast cutting speed, small inertia, and stable operation.

Assemble the torch correctly

Assemble the torch correctly

Install the cutting torch correctly and carefully, ensure that all parts are well matched, and ensure that the gas and cooling air flow. Install all the parts on a clean flannel to avoid dirt sticking to the parts. Add proper lubricating oil to the O-ring, subject to the brightening of the O-ring, and no more.

Consumable parts should be replaced in time before they are completely damaged

Do not replace the consumable parts after they are completely damaged, because severely worn electrodes, nozzles and swirl rings will produce uncontrollable plasma arcs, which can easily cause serious damage to the cutting torch. Therefore, when the cutting quality is found to be degraded for the first time, the consumable parts should be checked in time.

Clean the connecting thread of the cutting torch

When replacing consumable parts or daily maintenance and inspection, be sure to ensure that the internal and external threads of the cutting torch are clean. If necessary, clean or repair the connecting threads.

Clean the contact surface of the electrode and the nozzle

In many cutting torches, the contact surface between the nozzle and the electrode is a charged contact surface. If these contact surfaces are dirty, the cutting torch will not work properly and should be cleaned with hydrogen peroxide cleaning agent.

Check gas and cooling gas daily

Check the flow and pressure of the gas and cooling air flow every day. If you find that the flow is insufficient or leaks, you should stop the machine immediately to troubleshoot.

Avoid torch collision damage

In order to avoid collision damage to the cutting torch, it should be programmed correctly to prevent the system from overrun. The installation of an anti-collision device can effectively avoid damage to the cutting torch during collision.

The most common causes of torch damage

(1) The cutting torch collides.

(2) Destructive plasma arc caused by damage to consumables.

(3) Destructive plasma arc caused by dirt.

(4) Destructive plasma arc caused by loose parts.

Vorsichtsmaßnahmen

(1) Do not apply grease on the cutting torch.

(2) Do not overuse O-ring lubricant.

(3) Do not spray anti-splash chemicals while the protective cover is still on the cutting torch.

(4) Do not use the manual cutting torch as a hammer.

IGOLDEN CNC ist der führende CNC Router Designer, Hersteller und Exporteur seit 2003. Wir haben über 400 professionelle Mitarbeiter und über 70.000 Quadratmeter Fabrik. Unsere hochwertigen, innovativen Produkte umfassen ATC-CNC-Fräsen, CNC-Holz-Tür-Graviermaschinen und Faserlaser-Maschine, etc. OEM und ODM sind verfügbar. Unsere jährliche Produktion von CNC-Maschinen beträgt über 12.000 Sätze, die in über 136 Länder exportiert wurden. Wenn Sie Fragen oder Anfragen haben, füllen Sie bitte das folgende Formular aus und senden Sie es ab. Wir werden Ihnen so schnell wie möglich antworten.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.