CNC-Holzbearbeitungszentrum für Schneiden und Bohren

Item No.:CNC Drilling and Cutting Machining Center

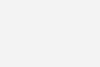

High-speed CNC drilling and cutting machining center is a set of drilling, grooving, cutting as one of the processing equipment, the machine is composed of automatic labeling machine, drilling area, cutting area three parts, only need to place the plate on the labeling platform, the machine can be automatic labeling, front and back drilling and grooving, cutting and other processing steps, can also be matched with edge sealing machine, The production process of panel furniture can be completed;

Beschreibung

Smart Wood CNC Cutting Drilling Machine

High-speed CNC drilling and cutting machining center is a set of drilling, grooving, cutting as one of the processing equipment, the machine is composed of automatic labeling machine, drilling area, cutting area three parts, only need to place the plate on the labeling platform, the machine can be automatic labeling, front and back drilling and grooving, cutting and other processing steps, can also be matched with edge sealing machine, The production process of panel furniture can be completed;

Equipment operation is simple, high efficiency, high precision, so that the production is more time saving, saving materials, saving labor, is the only choice for plate furniture enterprises.

Automatic Kitchen Cabinet Door Making Machine

Full automatic CNC router is mainly designed for customized furniture plans, such as kitchen cabinet and wardrobe, the whole production line only need one ordinary worker to operate.

1. Automatic Feeding

Suck the board to the next process automatically.

2. Automatic Labeling

The machine can show a barcode / order No. / board size information on each board. The label information can be customized according to your requirements.

3. Automatic CNC Machining

Cutting, milling, drilling and engraving automatically.

4. Automatic Discharge

After process, the boards are discharged automatically.

HQD tool change spindle

9KW spindle + large capacity tool library, can meet a variety of processes.

Automatische Beschriftung

Replace manual labeling dependence, attach the label before processing, truly realize intelligence, save labor, save time, and effectively avoid manual labeling errors.

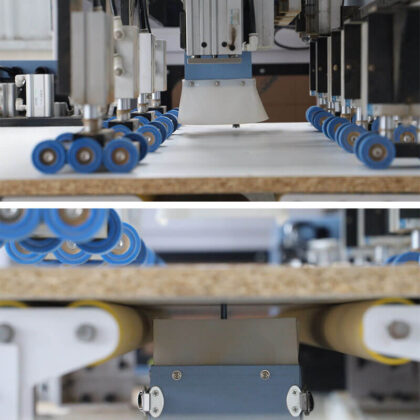

Automatic feed roller

The labeling is seamlessly connected to the drilling unit and self-transmitted, which is more efficient.

Double drill bag

Drill holes and grooves on both sides of the plate.

CNC Drilling and Cutting Machining Center Parameter

| Kontrollsystem | Taiwan SYNTEC system |

| Servo | INOVANCE 1.5KW servo |

| Processing Mode | Automatic labeling + feeding + double-sided punching + high-speed cutting + pushing |

| Punch unit | Double drill work at the same time |

| Slotted unit | Slot both top and bottom |

| Label the material | Independent automatic induction rotary labeling + automatic feeding |

| Clamp forceps | Double independent clamp |

| Reduzierstück | Japan SHIMPO |

| Führungsschiene | Taiwan HIWIN |

| Gestell | High precision grinding rack |

| Drill bag | HQD high torque drill pack |

| Spindel | HQD high speed spindle |

| Wechselrichter | Fuling |

| Magazine tool | 16 knife in-line knife library |

| Vakuumpumpe | 6.0KW variable-frequency vacuum pump |

| Dust collector | 7.5KW double vacuum cleaner |

| Blanking platform | Automatic sensing platform |

| Whole length | 14m |

| Gesamtgewicht | 5T |

Applications of Full Automatic Flatbed CNC Router

1. Furniture Industries

Cabinet doors, wooden doors, solid woods, plates, antique furniture, doors, windows, tables and chairs.

2. Decoration Industries

Screens, wave boards, large-size wall hangings, advertising boards and sign making.

3. Arts & Crafts Industries

Achieveing effects of exquisite patterns and characters on artificial stones, woods, bamboos, marbles, organic boards, double-color boards and so on.

4. Processing Material

Carving, milling and cutting for acrylic, PVC, density boards, artificial stones, organic glass, plastics and soft metal sheets such as copper and aluminum.

Full Automatic Flatbed CNC Router Advanced Performance

① Automatic labeling: completely replace the dependence on manual labeling, paste the label well before processing, truly realize intelligence, save labor, save time, and effectively avoid manual labeling errors;

(2) Bed integrated design: double side drilling unit and cutting unit integrated design, the whole plate and then the double side drilling unit drilling, directly and automatically transported to the cutting unit, higher accuracy; More efficient;

③ Reduce the production process: the plate drilling is completed in the opening drilling machine and the edge banding machine, the drilling link does not need manual intervention, eliminating the traditional edge banding and then manually get the drilling link on the six sides of the drill;

④ Improve production efficiency: the upper and lower drilling of the whole plate is faster and more efficient than the piece-by-piece processing of the smaller allegro;

⑤ Reduce the damage of the plate in the production process: while building the production process, it reduces the transmission and handling of the plate in the production process, effectively reducing the damage of the plate;

High degree of automation: compared with the traditional stand-alone equipment, the manual only needs to pick up the board and turn to the edge banding machine, which greatly improves the degree of automation in the production process;

Low failure rate, easy to operate: compared with traditional automated production lines, easier to operate, lower failure rate;

iGOLDENCNC, Ihre beste Wahl

Wenn Sie Kunde von iGOLDENCNC werden, werden wir mit Ihnen auf der Basis von Vertrauen und Komfort zusammenarbeiten. Sie werden feststellen, dass wir ein seriöser Lieferant sind und Ihr Vertrauen verdienen. Wir verstehen, dass jeder Kunde wertvoll ist, und wir werden jede Gelegenheit zur Zusammenarbeit zu schätzen wissen!

Strenges Qualitätskontrollsystem

Es werden fortschrittliche Prüfgeräte eingesetzt, wie z.B.: dynamisches Gleichgewichtsprüfgerät, CNC-Hochpräzisionsbearbeitungsmaschine, 3D-Messmaschine; iGOLDENCNC hat ein komplettes und strenges Qualitätskontrollsystem eingeführt, das einen 48-Stunden-Lauftest und einen 72-Stunden-Alterungstest umfasst, um die ausgezeichnete Qualität unserer Maschinen zu gewährleisten.

Benötigen Sie einen Katalog, einen Preis oder ein Arbeitsvideo der Maschine? Bitte teilen Sie uns Ihren Namen und Ihre E-Mail-Adresse mit, damit wir Ihnen so schnell wie möglich weitere Informationen zusenden können.

Schreibe die erste Rezension für „CNC Wood Cutting And Drilling Machining Center“

Du musst angemeldet sein, um eine Rezension veröffentlichen zu können.

Rezensionen

Es gibt noch keine Rezensionen.