Doppelt verwendbarer Faserlaserschneider für Bleche und Rohre

Item No.: iGR-FT

Dual-Use-Faser-Laserschneider, auch genannt Faser-Laser-Schneidemaschine, Laserschneider, Metall-Laser-Schneider, Metall-Laser-Schneidemaschine, für hohe Präzision Metallplatte Schneiden Verarbeitung konzipiert. Dieses Modell ist die Dual-Use-Modell für Metallplatte und Rohr schneiden zu einem erschwinglichen Preis.

Kategorie: Lasermaschinen>>Laserschneider

Reaktionszeit: Innerhalb von 1 Stunde

Lieferfähigkeit: 200 Sets/Monat

Preisspanne: $4850-$163500

Beschreibung

Who is Laser Cutting Machine for?

The most popular, dual-use fiber laser cutter, which can both cut metal sheet and tube, the welding body offers the robust construction that iGOLDENCNC products are known for, combined with a competitive set of configurations.

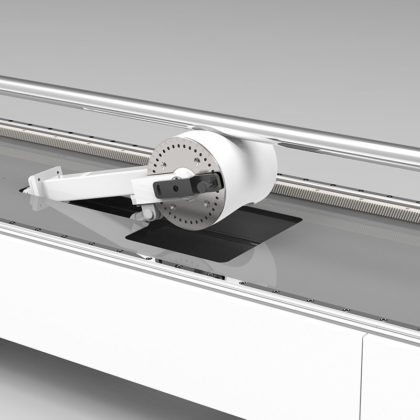

Pipe cutting capability: In addition to sheet cutting, a sheet and pipe laser cutting machine also includes a rotary axis or a chuck system that enables the cutting of cylindrical objects like pipes, tubes, or profiles. The machine can rotate the pipe while the laser beam cuts through the material, allowing for complex contours or precise end cuts.

The advantages of using a metal sheet and tube laser cutting machine include high precision, speed, and accuracy, minimal material waste, and the ability to cut complex shapes and designs.

Was macht sie einzigartig?

Popular with metal processing users, the iGR-FT series fiber laser cutter is suitable for manufacturers who just joined the industrial or started the metal cutting business.

>Dual-use model, low cost;

>High precision, perfect cutting result;

>Schwerindustriequalität, stabiler Betrieb seit 10 Jahren;

>Einfache Bedienung, schnelle Hindernisbeseitigung, lernfördernd;

>Unterstützt vom Branchenführer iGOLDENCNC.

Hot applications are cutting for stainless steel, carbon steel, aluminum, copper, galvanized sheet and another metal plate and tube.Metal sheet and tube laser cutting machines are commonly used in industries such as aerospace, automotive, and construction, where precision cutting of metal components is required.

Application of Fiber Laser Cutter Machine

Stainless Steel Cutting

Metal Round Tube Cutting

Carbon Steel Cutting

Cutting for Hardware

Metal Square Tube Cutting

Cutting for Car Parts

Cutting for Metal Box

Cutting for Metal Shelf

| Positionierungsgenauigkeit | 0,03 mm |

| Repeat Positioning Accuracy | 0,02 mm |

| Laserleistung | 750w/1000w/1500w/2000w/3000w |

| Max. Loading Weight | 800KG |

| Max. Speed | 25000mm/min |

| Max. Acceleration | 1.5G |

| Cooling System | Wasser-Kühlung |

| Stromversorgung | 380V/50-60Hz |

| Working Area | 3000*1500mm |

| Abmessungen | 8100*3750*2200mm |

| N.W | 3500kg |

Features of Fiber Laser Cutter Machine

Options of Fiber Laser Cutter Machine

For the fiber laser cutter, the price is different according to the function and configuration. Please contact us for more details.

It depend on the material thickness you want to processing and the running frequency of the machine. Please let us know which material do you want to process and the thickness.

The metal laser cutter is only for metal sheet, such as stainless steel, carbon steel, copper, aluminum, iron, galvanized, etc..

Verwandte Produkte

Benötigen Sie einen Katalog, einen Preis oder ein Arbeitsvideo der Maschine?

Bitte teilen Sie uns Ihren Namen und Ihre E-Mail-Adresse mit, damit wir Ihnen so schnell wie möglich weitere Informationen zusenden können.

Schreibe die erste Rezension für „Dual-use Fiber Laser Cutter for Metal Sheet and Tube“

Du musst angemeldet sein, um eine Rezension veröffentlichen zu können.

Rezensionen

Es gibt noch keine Rezensionen.