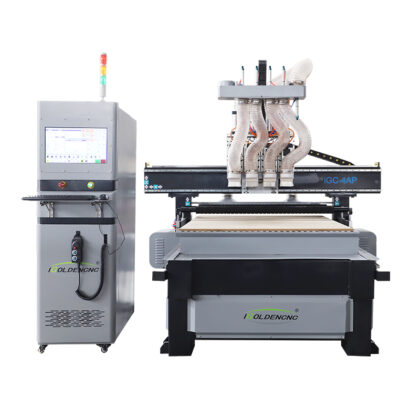

CNC Four Process Wood Cutting Machine,Holzbearbeitung 4 Prozess Schneidemaschine

Item No.: iGC-4AP

iGC-4AP wood CNC router machine is mainly used for wood door making, cabinet making, sign making, furniture making, decoration making and other popular woodworking. Now the best 4×8 wood CNC machine for sale at an affordable price.

Category: Furniture CNC Machine>>Cabinet Maker

Reaktionszeit: Innerhalb von 1 Stunde

Lieferfähigkeit: 300 Sets/Monat

Price Range: $13030-$15030

Beschreibung

Who is wood cutting machine for?

The most popular multifunctional ATC CNC router machine designed by iGOLDENCNC, suitable for a variety of complex product processing or diverse processing. It can automatically change tools during work and provides a set of competitive configurations. Popular applications include:

>Production and processing of various types of furniture: cabinets, wardrobes, office furniture, computer tables, children’s furniture, panel furniture, cutting and cutting, slotting and perforating, decoration hollow frames, soft bag background wall production, etc;

>Holztür- und Möbeldekorationsindustrie: Massivholz- und Verbundtüren, Schranktüren, großflächige Plattenschnitzereien, Massivholz- und Paneelmöbelschnitzereien, Wandschnitzereien aus Massivholz, etc;

>Holzverarbeitung: Uhren, elektrische Arbeitsplatten, Sportartikel und -geräte;

>Musikinstrumentenindustrie: Dreidimensionales Schneiden von gekrümmten Oberflächen und Formen für modellierbare Musikinstrumente;

>Crafts industry: photo frames, jewelry boxes.

What makes CNC wood cutting machine unique?

The iGC-4AP series ATC CNC router machine is very popular in the cabinet manufacturer and door manufacturer. It improves the efficiency of wood processing. It is specially designed for cabinet doors and panel furniture production lines.

Anwendungen der ATC CNC-Fräsmaschine

1.Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

2.Wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

3.Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

4.Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Wooden Door Making

Wooden Bed Processing

Wood Slotting

Wood Hollowing

Soft Wall Processing

Office Furniture Making

Kitchen Cabinet Making

Customized Closet Making

| Machine stroke | 1300mm *2500mm |

| X axis travel | 1300mm |

| Y axis travel | 2500mm |

| Z axis travel | 200mm |

| File format | G-Code |

| Workbench structure | A-grade hard special vacuum adsorption table + Pressure roller |

| Operating Voltage | 380V/50HZ |

| Bed frame | Heavy-duty stable bed |

| Spindel | HQD 6KW air-cooled tool change spindle*2 + 4.5KW *2 |

| Drive System | Servo motor drive |

| Kontrollsystem | Taiwan LNC + wireless handwheel |

| Gestell | Taiwan high precision rack |

| Leitfaden | Taiwan HIWIN+Original Slider |

| Lead screw | Taiwan screw |

| Wechselrichter | FULING |

| Kabinett | Independent cabinet |

| Staubsammelsystem | Floating dust collection + central dust collection structure |

Features of ATC CNC Router Machine

Hochpräzises Übertragungssystem

Die Positioniergenauigkeit der Maschine beträgt 0,02 mm, die maximale Laufgeschwindigkeit 50.000 mm/min, und die Lebensdauer der Maschine beträgt bis zu 10 Jahre.

Optionen der ATC CNC-Fräsmaschine

Alle Maschinenteile nehmen hohe Konfigurationen, höhere Arbeitseffizienz. Es ist der Wechsel der Werkzeuge durch automatische, keine Notwendigkeit ändern von Hand, sparen Sie Zeit und Arbeitskräfte.

Unsere ATC-Maschine dieser Art unterstützt viele Werkzeuge, jedes Werkzeug hat verschiedene Funktionen, kann gravieren, schneiden, polieren, verschiedene Formen und Muster auf dem Blech machen.

We set up a special QUALITY CONTROL DEPARTMENT inside of the factory. Therefore there is a strict control for each process, and we have regulated the standards for welding process, machining process, assembly process, manufacturing process and packaging process, etc.

Ja, wir können das Ölnebelsystem für Sie hinzufügen, es kann zur Kühlung der Schneidwerkzeuge und Materialien verwendet werden.

Wir werden das Handbuch mit der Maschine zusammen an Sie senden, wir werden auch volle Operation Video zu Ihnen nehmen, um Ihnen zu helfen, Maschine gut zu benutzen.

A woodworking 4 process cutting machine is a type of machine used for cutting and processing wood. It typically includes four different cutting processes, such as sawing, drilling, milling, and routing. This type of machine is commonly used in woodworking shops, furniture factories, and other woodworking industries.

The sawing process is used to cut large pieces of wood into smaller, more manageable sizes. The drilling process is used to create holes in the wood for dowels or other fittings. The milling process is used to shape the wood into more complex shapes, such as curves or angles. The routing process is used to create decorative edges or designs on the wood.

A woodworking 4 process cutting machine can be either manually operated or computer-controlled, depending on the complexity of the cutting processes and the desired level of precision. Computer-controlled machines typically use CAD/CAM software to program the cutting paths and automate the cutting processes. When shopping for a 4 process woodworking cutting machine, it’s important to consider factors such as cutting capacity, cutting accuracy, control system, and price. Additionally, it’s important to ensure that the machine is well-maintained and supported by the manufacturer or supplier.

Schreibe die erste Rezension für „CNC Four Process Wood Cutting Machine,Woodworking 4 process cutting machine“

Du musst angemeldet sein, um eine Rezension veröffentlichen zu können.

Rezensionen

Es gibt noch keine Rezensionen.