CNC-Schaumstoffschneidemaschine für EPS, EPP, XPS

Item No:: iGF-C

CNC Foam cutter, also known as electric heating wire foam cutting machine, CNC foam cutting machine, can be used for material cutting and 3D mold making of polystyrene foam (EPS), polypropylene plastic foaming material (EPP), XPS extruded board.

Kategorie: CNC-Router >>CNC-Schaumstoffschneider

Reaktionszeit: Innerhalb von 1 Stunde

Lieferfähigkeit: 200 Sets/Monat

Preisspanne: $17000-$19000

Beschreibung

Für wen ist es gedacht?

>Cutting woven rubber sheet, pearl cotton, foamed rubber sheet, extruded plastic sheet and other grooves, rubber sheet and rubber rod;

>Cut the tubular webbing;

>Cut thin chemical fiber cloth (such as curtain cloth, advertising cloth, white painting, etc.);

>Cutting chemical fiber carpets and thin plastic walls;

>Cut off the corners of office furniture decorative fabrics (such as screen fabrics);

>Eliminate grease or organic stains on the surface of ceramic tiles;

>EPS foam cutting machine can cut the plastic workpiece gate (gate) material and so on;

>Cut various foam boards.

Was macht sie einzigartig?

The iGF-C series is very popular among foam processors, can save labor and time, and is specially designed for foam processing.

>For cutting EPS/Polypropylene/EPP/XPS;

>Der Materialausnutzungsgrad ist so hoch wie 98% und spart Materialkosten;

>Schwerindustriequalität, stabiler Betrieb seit zehn Jahren;

>Die Bedienung ist einfach und die Hindernisse sind schnell überwunden, was dem Lernen förderlich ist;

>Unterstützt vom Branchenführer iGOLDENCNC.

Anwendungen der CNC-Schaumstoffschneidemaschine

Wooden Crafts Making

Kunststoffformenbau

Auto-Formenbau

Foam Mold processing

3D-Schaumstoff-Formenbau

Doll Model Carving

EPS-Formenbau

Aluminium Formenbau

| Positionierungsgenauigkeit | ±0,05 mm |

| Genauigkeit bei der Neupositionierung | ±0.04mm |

| Befehlssprache | G-Code |

| Flash-Speicher | 128G |

| Max. Schnellreisegeschwindigkeit | 5000mm/min |

| Max. Arbeitsgeschwindigkeit | 800mm/min |

| Arbeitsspannung | 380V/50Hz |

| Temperatur der Betriebsumgebung | Über 25℃ |

| Relative Luftfeuchtigkeit | <85% |

| Ps. Die Einstellung ist je nach örtlicher Anforderung möglich | |

| Arbeitsbereich (X,Y,Z) | 3000*1300*1300mm |

| Packungsgröße | 3600*2000*1500mm |

| N.W./G.W. | 1000KG |

| Arbeitsbereich (X,Y,Z) | 3000*2000*1300mm |

| Packungsgröße | 3600*2700*1500mm |

| N.W./G.W. | 1500KG |

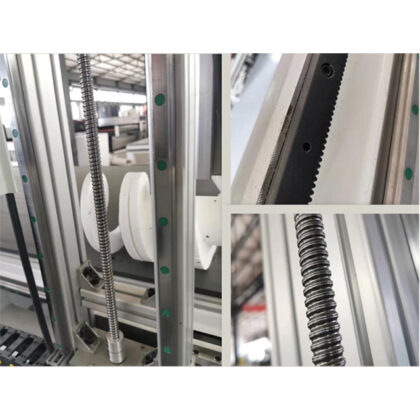

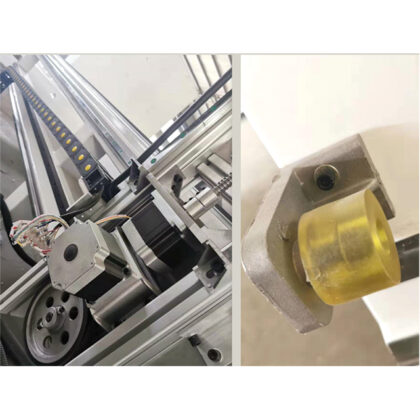

Features of CNC foam cutting machine

Optionen der CNC-Schaumstoffschneidemaschine

This machine can make foam such as EPS, also can make wood such as MDF, thin-metal such as aluminum, plastic such as acrylic.

Travel speed is 50000mm/min,working speed is 25000mm/min.

Yes, can add rotary for achieve cylindrical carving as your requirement.

Natürlich können Sie uns Ihr Design schicken, wir können ein Muster erstellen und ein Video für Sie aufnehmen.

Verwandte Produkte

Benötigen Sie einen Katalog, einen Preis oder ein Arbeitsvideo der Maschine? Bitte teilen Sie uns Ihren Namen und Ihre E-Mail-Adresse mit, damit wir Ihnen so schnell wie möglich weitere Informationen zusenden können.

Schreibe die erste Rezension für „CNC Foam Cutting Machine for EPS, EPP, XPS“

Du musst angemeldet sein, um eine Rezension veröffentlichen zu können.

Rezensionen

Es gibt noch keine Rezensionen.