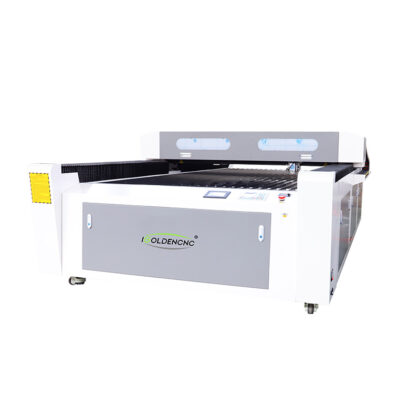

Gemischte Lasergraviermaschine für Metalle und Nichtmetalle

This CNC CO2 mixed cutting laser cutting machine is suitable for cutting metal and non-metal plates. It adopts a steel welding frame, which is stable, has good rigidity, and high dynamic response, ensuring that it will not be deformed for a long time.

Category: Laser Machine>>Laser Engraver

Reaktionszeit: Innerhalb von 1 Stunde

Lieferfähigkeit: 300 Sets/Monat

Price Range: $3650-$4950

Beschreibung

Laser Cutting Engraving Machine iGR-BM

The multi-function laser cutting head is suitable for cutting metal and non-metal materials. The fixed optical path compensation system ensures the consistency of the laser spot quality in the entire cutting area. The imported linear guide rail and lead screw conveying system have high rigidity, large transmission torque, eliminate vibration, and the accuracy is several times higher than that of the belt drive system.

The self-developed new generation of touch screen motion controllers is designed with touch screen software. The control system supports automatic focusing of metal cutting and non-metal processing, and can easily cut materials of various thicknesses with good results.

Engraving laser machine details

CO2 Laser Cutting Machine Features:

◎High processing efficiency, 10 to 15 times that of manual engraving; high precision, low cost, and good printing effect;

◎The optimized design of the mechanical structure and the smallest overall size of the whole machine not only saves your precious space, but also the structure should not be deformed and the cutting precision is high;

◎Taiwan square linear guide, long life;

◎The use of patented technology makes the engraving effect of the rubber plate better, and it is not easy to burn;

◎Genuine laser engraving software, powerful; engraving and cutting can be carried out at the same time.

Laser Engraving Machines Application

> Handicraft industry: exquisite patterns and characters are carved on wood, bamboo chips, ivory, bones, leather, marble, shells and other materials;

> Advertising industry: mainly used for two-color plate engraving, acrylic engraving and cutting, sign engraving, crystal, trophy engraving, license engraving, etc.;

> Leather garment processing industry: complex text and graphic engraving, cutting, engraving and hollowing out on synthetic leather, artificial leather, fabric, and fur; cutting, cutting, Sculpting, beyond fashion, showing individuality;

> Model industry: making sand table building models, aircraft models;

> Packaging industry: engraving and printing rubber sheet, plastic sheet, double-layer sheet, die-cutting blade, etc.;

> Other industries: engraving marks on decorative materials such as marble, granite, glass, crystal, paper cutting, greeting cards and other paper craft cutting.

Was ist Laser gemischt Schneidemaschine?

Der Kohlendioxidlaser ist ein Gasmoleküllaser. Die Arbeitssubstanz ist CO2-Gas, und die Hilfsgase sind Stickstoff, Helium, Xenon und Wasserstoff. Da die Energieumwandlungseffizienz dieses Lasers bei 25% liegt, wird er häufig als Laser mit hoher Ausgangsleistung eingesetzt. Die Wellenlänge des Kohlendioxidlasers liegt bei 10,6 Mikrometern. Es ist unmöglich, infrarotes Licht zu sehen, hat eine gute Stabilität und ist weit verbreitet.

Durch den Einsatz der weltweit fortschrittlichsten DSP-Steuerungstechnologie, der erstklassigen Funktion zum kontinuierlichen und schnellen Kurvenschneiden und der Funktion zur Optimierung des kürzesten Bearbeitungswegs wird die Arbeitseffizienz erheblich verbessert. Während des gesamten Graviervorgangs wird automatisch eine Kompensation der Lichtabschwächung durchgeführt, um einen gleichmäßigen Schnitt in verschiedenen Bereichen zu gewährleisten. Das Design der Schnellschnitt-Steuerungssoftware und die Pufferfunktion während der Hochgeschwindigkeitsbewegung können die Produktionseffizienz verbessern.

Laser Engraving Machine Advantages

With multi-functional detail design, it is more humane, flexible and convenient.Adopting stable laser device, who’s the maintenance cost is low. With the features of compact design and simple structure, it is more convenient to operate. Imported high-precision ball screws and guides are adopted for stable driving and high working accuracy.

How to choose the right laser engraver machine?

1.Material to be carved:

Determine the type of material to be engraved. At present, the CNC laser engraving machine on the market can be roughly divided into non-metal laser engraving machine and metal laser engraving machine. The former is specially used for engraving and cutting of non-metallic materials, while the latter can be used for metal materials. Processing.

2.Laser power:

Choose the appropriate laser power according to the material to be processed. For some materials, such as acrylic, two-colour plates, etc., high-power laser tubes are not required, but for some other materials, such as stone, wood and other harder materials, Higher power is required. The excellent working performance will require a power laser tube.

[su_accordion class=""][su_spoiler title="Klicken Sie, um mehr zu sehen." open="no" style="default" icon="plus" anchor="" class=""]

- Working size:

Different applications require laser engraving machines with different working sizes. Generally, laser engraving machines of models 6040, 9060, 1290, 1390, 1490, 1610, 1612, 1812 can be used, for example, the working size of model 6040 is 600*400mm. Different Work scale and different prices. For example:

1) Rubber pad, rubber sheet, carton board: most laser engraving machines can be used to engrave on rubber sheets. The material does not require some special and fast machines, so it is recommended to use a laser engraving machine suitable for engraving rubber sheets, which is cheap, The investment is small, but the return is fast.

2) Bamboo, greeting cards, paper-cut gifts, wooden crafts, small ornaments, carved wooden boxes, wine boxes, bamboo tubes, tea tubes, crystal glass ornaments, acrylic crafts, etc., choose small machines, such as 9060 laser engraving machine (900X600mm), the price is extremely high Competitive, high precision, equipped with lifting platform and free replacement platform, can be widely used in various materials and profiles.

3) Acrylic plate: Most laser engraving machines can be used to cut acrylic plates, however, it is recommended to use a dedicated laser cutting machine. Because the laser cutting machine is optimized for laser cutting and has excellent cutting results. Usually: 60W laser engraver can Cut 8-10mm acrylic. 80w laser engraver can cut 8-15mm acrylic.

4) Clothing, leather: Choose a suitable laser engraving machine, which has a fast cutting speed and is equipped with a honeycomb cutting platform.

- Engraving speed;

On the premise of excellent engraving effect, pay attention to the working speed of the machine. Only when you produce more products in a short time, you can create higher profits.

- Engraving accuracy;

The biggest difference between a laser engraving machine and traditional engraving equipment with manual engraving is the engraving accuracy. For fine project drawings, the engraving accuracy requirements are relatively high.

- Machine quality;

1) Stepper motor: It will affect the engraving accuracy of the CNC laser engraving machine. There are different types of stepper motors available, including imported ones, household ones, high-quality ones and inferior ones, etc.

2) Laser lens: It affects the power of the laser engraving machine. It can be divided into imported lenses, domestic lenses, and domestic lenses can be divided into imported materials and domestic materials. The price difference is very large, and the work effect and service life are also in this way.

3) Laser tube: the heart of laser engraving machines. Most household laser engraving machines use domestic laser tubes.

4) Machine tools: When selecting, pay special attention to the quality of the machine, especially the thickness and strength of the structure.

What is Laser Engraving And Cutting Machine?

The laser machine is the general term for laser engraving machines, laser cutting machines, and laser marking machines. The laser machine uses its high-temperature working principle to act on the surface of the processed material, and at the same time draws patterns and texts required by customers based on the graphics input into the machine.

How to Buy a laser engrave machine?

- Inquiry. Feel free to tell us what material you want, what is your max working size, and what product you want to do. The budget is also welcome.

- Kostenloses Angebot erstellt. Wir senden Ihnen unser Angebotsblatt mit Maschinenkonfiguration, Fotos, Videos und Preisen entsprechend Ihrer Anfrage zu.

- Starten Sie die Bestellung. Ihr Unternehmen wird die Anzahlung, und wir beginnen die Maschine Produktion von 3D-Design, Maschine Körper Schweißen, Bearbeitung, Malerei Ersatzteile Vorbereitung, Herstellung und Prüfung.

- Testing sample video and delivery. After our manufacture and inspection, we will make a final video of the machine working for you. After the confirmation, the machine will be shipped by sea through my or your agent.

- Service nach dem Verkauf. Wir bieten ein Video-Lehrprogramm, um den Kunden zu erklären, wie man unsere Maschine benutzt oder installiert. Und mein Service-Team wird 7*24 Stunden online, um Kundenfragen zu beantworten.

- Rückmeldung. Wir erwarten ein Feedback von unseren Kunden. Bitte teilen Sie uns mit, was Sie von der Qualität und dem Service der Maschine halten. Wenn Sie weitere Ideen haben, um uns zu helfen, zu verbessern, wird das sehr geschätzt werden.

[/su_spoiler]

[/su_accordion]

Benötigen Sie einen Katalog, einen Preis oder ein Arbeitsvideo der Maschine?

Bitte teilen Sie uns Ihren Namen und Ihre E-Mail-Adresse mit, damit wir Ihnen so schnell wie möglich weitere Informationen zusenden können.

Schreibe die erste Rezension für „Mixed Laser Engraver Machine for Metal & Nonmetal“

Du musst angemeldet sein, um eine Rezension veröffentlichen zu können.

Rezensionen

Es gibt noch keine Rezensionen.