Computerisierte Balken Säge Holzbearbeitung Panel Säge Maschine zu verkaufen

Item No.: IGC-PS

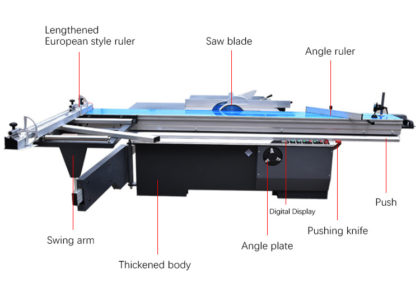

This panel saw cutting machine use mobile worktable is pushed by hand to move back and forth to realize sawing processing. The scoring saw performs sawing in advance, and the main saw blade can use the tower wheel to change speed for sawing. The manual feed is light and labor-saving, the machining accuracy is high, and the good cutting quality is obtained.

Die Führungsschiene des beweglichen Arbeitstisches besteht aus einer hochfesten, stranggepressten Aluminiumlegierung mit hoher Festigkeit, ohne Verformung, verchromter Rundstabstruktur, hoher Positioniergenauigkeit und Oxidationsbehandlung auf der Oberfläche des Arbeitstisches, die schön und verschleißfest ist. Die Tischsäge kann für dichte Platten, polierte Platten, Holzwerkstoffplatten, Massivholzplatten, ABS-Platten, PVC-Platten, etc. verwendet werden. Schneiden von Platten.

Category: Furniture Making Machine >> Cabinet Maker

Reaktionszeit: Innerhalb von 1 Stunde

Lieferfähigkeit: 300 Sets/Monat

Price Range: $1500-$2300

Beschreibung

Für wen ist es gedacht?

The panel saw cutting machine designed by iGOLDENCNC is used in conjunction with panel furniture making machine and six-sided drilling machine.

It is suitable for processing many kinds of board materials such as density board, particleboard, artificial board, solid wood board, plexiglass, PVC board, ABS board for board furniture, whole cabinet, wardrobe, customized furniture, office furniture that need to be cutting.

Was macht sie einzigartig?

The iGC-PS series is very popular in wardrobe factories, cabinet factories and furniture factories. It improves the efficiency of board cutting, and it can be used with the opener to automate the production of furniture in the assembly line.

>Automatic detection, intelligent punching;

>high processing efficiency, reducing labor costs;

>Input memory, multiple modes can be switched freely;

>Einfache Bedienung, schnelle Hindernisbeseitigung, lernfördernd;

>Unterstützt vom Branchenführer iGOLDENCNC.

Applications of Side Hole CNC Drilling Machine

45 degree cutting

wood cutting process

90 degree cutting

solid board cutting

90 degree processing

panel making

cutting 45 degree board

MDF-Zuschnitt

| Max Sawing length | 2800mm/3000mm/ 3200mm |

| Max Sawing width | 1250mm |

| Max sawing thickness | 80mm |

| Spindeldrehzahl | 4000/6000rpm |

| Scoring speed | 8000r/min |

| main motor power | 5.5KW |

| Auxiliary motor power | 0.75kw |

| Saw blade diameter | φ300(φ250-φ350mm) |

| Master shaft diameter | φ40 |

| Scoring saw diameter | ∮120mm |

| Ps. Die Einstellung ist je nach örtlicher Anforderung möglich | |

| Arbeitsbereich (X,Y,Z) | 3200×375mm |

| Gross weight | 840KG |

| Gross weight | 750KG |

Features of Side Hole CNC Drilling Machine

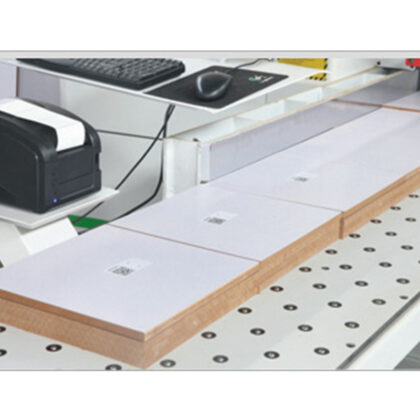

1. According to the input plate width, cut the required plate and quickly return to the original working state.

2. Cutting speed is controlled by frequency converter, which can overcome plates of different thickness and different materials.

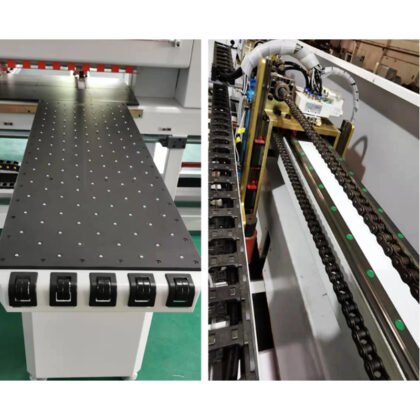

3. The feeding adopts pneumatic floating bead table, and the heavy plate material is easy to change. The robot automatically feeds, has low labor intensity and high production efficiency.

4. Use imported Delta servo motor to eliminate artificial error and improve dimensional accuracy.

Features of Panel Saw Cutting Machine

Customized is Available

The setting of the mobile worktable and the main saw blade can be adjusted at 45 degrees, which expands the range of use of the saw. The table saw can be applied to density boards, polished boards, wood-based boards, solid wood boards, ABS boards, PVC boards, etc.

Sliding table saw length 2800mm3000mm3200mm.

45 degrees, 90 degrees can be choose.

standard and high configuration according to your needs。

Please tell me what’s material you want to cutting or engraving ?

And what’s MAX size of carved material ? Do you mainly engrave or cut? If cut,What is your Max.cutting thickness? would you mind showing me your sample pictures?

We set up a special QUALITY CONTROL DEPARTMENT inside of the factory.Therefore there is a strict control for each process,and we have regulated the standards for welding process, machining process, assembly process, manufacturing process and packaging process,etc.

we offer Type3, ArtCAM software with machine.

Benötigen Sie einen Katalog, einen Preis oder ein Arbeitsvideo der Maschine?

Bitte teilen Sie uns Ihren Namen und Ihre E-Mail-Adresse mit, damit wir Ihnen so schnell wie möglich weitere Informationen zusenden können.

Schreibe die erste Rezension für „Computerized Beam Saw Woodworking Panel Saw Machine for Sale“

Du musst angemeldet sein, um eine Rezension veröffentlichen zu können.

Rezensionen

Es gibt noch keine Rezensionen.