Warum sollten Sie sich für ein 4-Achsen-CNC-Bearbeitungszentrum und eine Fräsmaschine entscheiden?

Was ist die 4-Achsen-CNC-Bearbeitungszentrum Fräsmaschine?

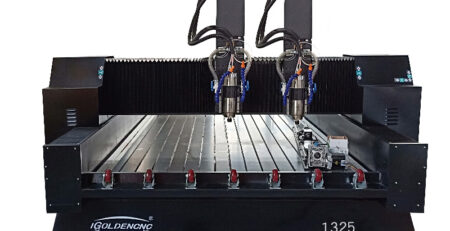

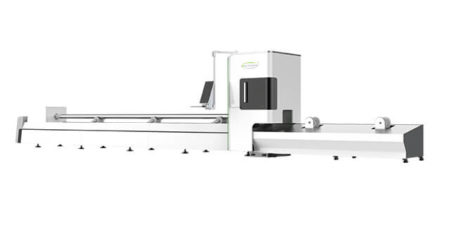

EPS-CNC-Fräse 4-Achsen-CNC-Bearbeitungszentrum FräsmaschineDie Spindel kann um 180° schwenken, optional können 8 lineare Werkzeugwechsler ausgewählt werden, um den Bedürfnissen verschiedener Bearbeitungstechnologien gerecht zu werden, 3D-Gravur in vollem Umfang und gekrümmte Oberflächenbearbeitung ist verfügbar, auch bekannt als Schaumstoff-CNC-Router-Maschine, Schimmel-CNC-Router-Maschine, EPS CNC-Schnitzmaschine.

Milling is an important technique used in CNC precision machining having applications for medical, aerospace, optical, as mechanical parts. Milling uses rotary cutters to remove material from a workpiece by feeding the workpiece at an angle to the axis of the tool. The axes that a milling machine has, determines the type of work and the locations in which it can be done on the workpiece.

What Benefits?

4-axis milling involves the same processes involved in 3-axis machining, where a cutting tool is used to remove material from a piece to create the desired shape and profile. However, in the case of 4-axes machining, milling is performed on an additional axis. A 4-axis CNC machine operates on the X,Y and Z axes like a 3-axis machine, but it also includes rotation around the X-axis, which is called the A-axis. This is the 4th axis that’s added to our machining process. In most cases, the workpiece will be rotated to allow for cutting to occur around the B-axis.

4-axis milling is useful when holes and cut-outs need to be made in the side of a piece or around a cylinder. They can provide quick and efficient work based off computer numerical inputs for precise results.

Why Choose 4 Axis CNC Machining?

4 Axis CNC machining involves a total of four degrees of freedom. That means either the tool or the workpiece can be moved/rotated along four axes. So, the workability is apparently higher than 3 Axis CNC machining.

Having the 4th axis allows the manufacturing of more complex parts. It is also be used to increase the number of parts you can work with at a time. So, manufacturers highly prefer 4 Axis CNC machining as an economic method for increasing production capabilities.

4 Axis CNC machining Working Principle

4 Axis CNC machining works almost similarly to 3 axis CNC machining, except that it includes an additional rotational axis for the workpiece. The cutting tool can move along the X, Y, and Z-axis just like how a 3 axis milling machine would perform.

An additional rotating mechanism is set up on the table which functions as the 4th axis. It is also called the A-Axis. Usually, a cylindrical workpiece is clamped into it and the workpiece is rotated to perform machining from different angles. So, the part can be machined without any setup change.

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.